3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

Do a test print on something smaller (and cheaper!), if it's a z issue it should occur based on height right? So print something relatively tall and thin.

No weird properties/looks on the stuff that did print?

(Relative noob myself here)

I've had a few smaller prints go off without any problems, but could always give something a little taller a go just to be safe.

It could be layer adhesion being hampered by bed temp. What are you printing in? Does it have a lot of warping at the corners?

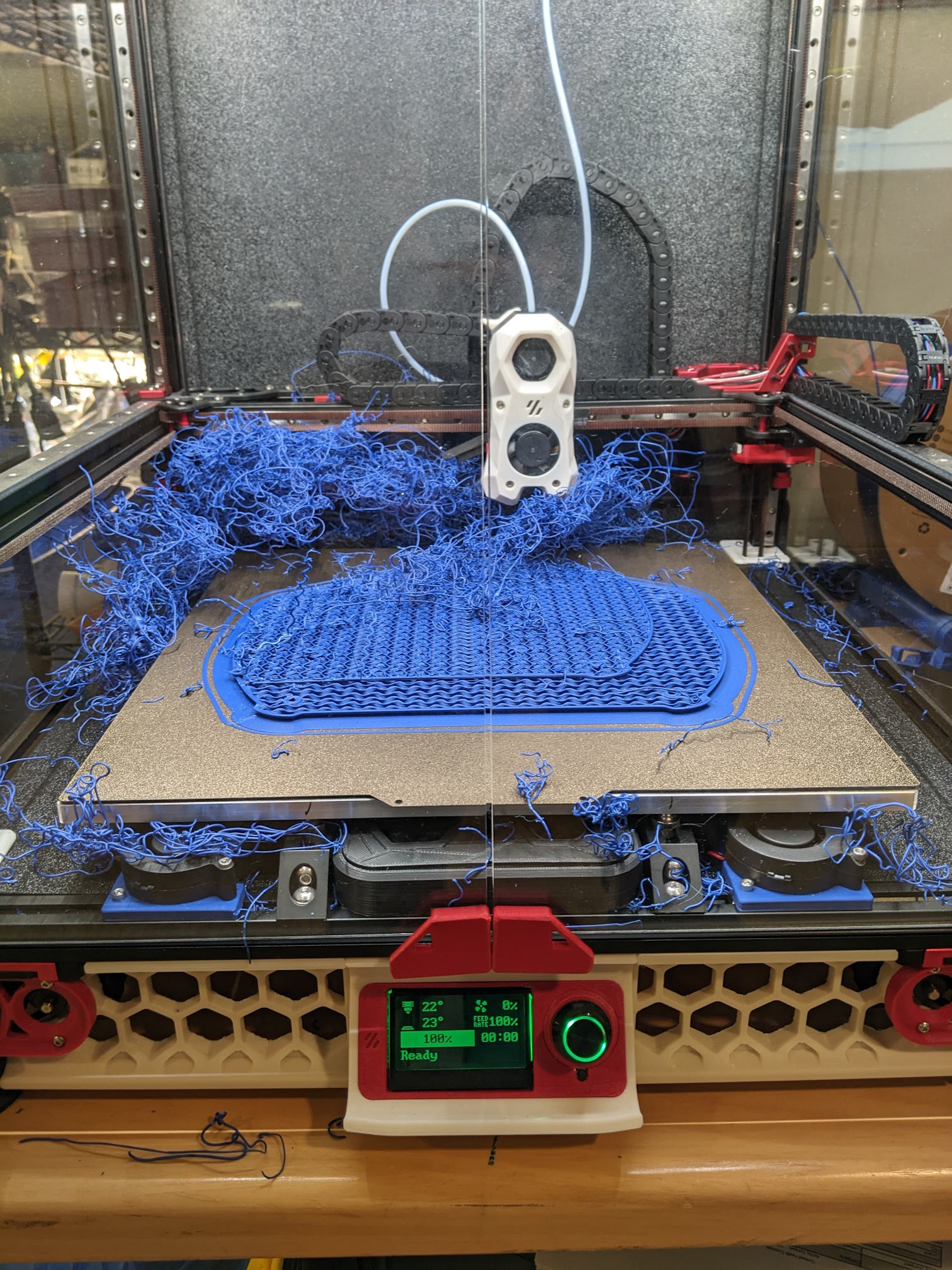

I think I found what was happening. Z hop was off and as the nozzle traveled at warp speeds over the print it was touching the prior layer ever so slightly. I think it snagged the infill in this print. Trying again with a hotter extruder and z-hop on.

It's printing in an acrylic enclosed Voron 2.4. Zero warping.