Brussels recognises ‘potential role’ for small reactors in decarbonisation efforts.

The European Commission (EC) has given formal start of a European Industrial Alliance on Small Modular Reactors (SMRs) along with non-binding recommendations to further cut greenhouse gas emissions by 2040 with the ultimate goal of achieving climate neutrality by 2050.

The Commission said in a statement on Tuesday 6 February that based on a conducted impact assessment it recommends a 90% net emissions reduction by 2040 compared to 1990 levels. A legislative proposal is expected to be made by the next Commission, after the European elections in June 2024.

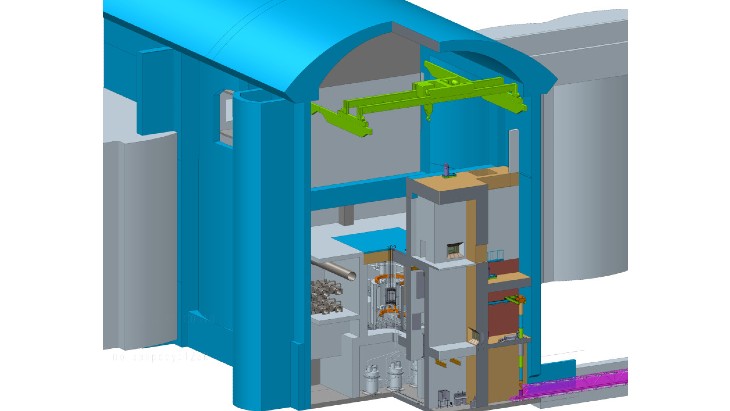

The EC said it recognises the potential contribution of SMRs to achieving the bloc’s green energy and climate objectives.

The establishment of an SMR industrial alliance aims to improve industrial competitiveness and ensure a strong EU supply chain and a skilled workforce, said the Commission.

According to EC, the European energy sector is to achieve full decarbonisation shortly after 2040, based on all zero and low carbon energy solutions, including renewables, nuclear, energy efficiency, carbon capture and storage, carbon removals, geothermal and hydro.

“An important benefit of these efforts [decarbonisation] is a lower dependence on fossil fuels thanks to an 80% fall in their consumption for energy from 2021 to 2040,” the EC said.

“The post-2030 policy framework will be an opportunity to develop these policies further and complement them with social and industrial policies to ensure a smooth transition away from fossil fuels.”

European Industrial Alliance On SMRs

Yves Desbazeille, director-general of Brussels-based nuclear industry group nucleareurope, welcomed the formation of the SMR industrial alliance and said the European nuclear industry “has been at the forefront of innovation and industrial excellence for decades.”

However, he said there are challenges which need to be addressed to ensure the smooth deployment of SMRs and the Commissions initiative can help overcome those challenges.

“The deployment of SMRs will bring significant benefits to Europe, including greater energy sovereignty, lower CO2 emissions, new jobs and economic growth,” said Desbazeille.

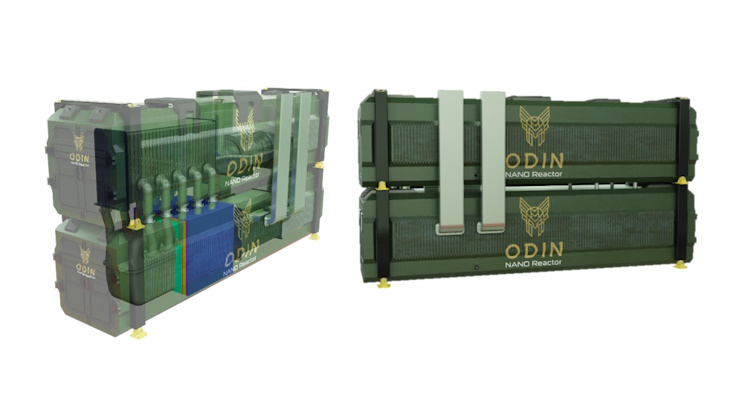

The SMR industrial alliance – which will bring together industry, policymakers, regulators and the public – will focus on accelerating the deployment of SMR technologies in the early 2030s.

In June 2021, the Commission organised its first workshop on SMR reactor technology in response to calls from the nuclear industry, led by nucleareurope.

The event resulted in a proposal to set up a European SMR partnership involving industrial stakeholders, research organisations, potential customers, utilities, member states and European policymakers and regulators. The aim would be to create “enabling conditions” for the first European SMRs to start operating early next decade.

Under the partnership proposal, five work streams were established to focus on aspects relevant to SMR deployment: potential market for SMRs, licencing issues, financing, supply chain adaptation and R&D. A working group was assigned to each stream.

In November 2023, the Commission proposed the formation of an SMR industrial alliance at a nuclear conference in Bratislava.

Nucleareurope said an EC action plan will identify a list of technically mature and commercially viable SMRs that could be supported under the industrial alliance, as well as potential gaps in the European supply chain for SMRs, including fuel and raw materials.

The plan should also identify investment barriers, funding opportunities and new financing options to support SMR development, while future needs for research on SMRs and existing skills gaps are to be addressed under the Euratom research and training programme, and at national level.

Yves Desbazeille previously said an SMR industrial alliance would also ensure cooperation on licensing issues across EU member state regulators.

The Commission is expected to open a call for members to join the SMR alliance shortly.

In December 2023, nuclear power was added to the EU’s list of “strategic” technologies as part of a draft net-zero industry bill which means it would benefit from improved investment conditions and streamlined licensing procedures. Nuclear energy, including SMRs, made it to a provisional deal announced 6 February and expected to be adopted later this year.

EU Green Policies Aim For Climate Neutrality By 2050

According to the EC, setting a 90% emission reduction target by 2040 will help European industry, investors, citizens and governments to make decisions in this decade that will keep the EU on track to meet its climate neutrality objective in 2050.

Such a policy will send “important signals” on how to invest and plan effectively for the longer term, said the Commission, adding it will boost Europe's resilience against future crises, strengthening the EU's energy independence from fossil fuel imports.

The European Climate Law, effective since July 2021, commits the EU to achieve climate neutrality by 2050 and reduce greenhouse gas emissions by at least 55% by 2030.

To meet these goals, the EU introduced the Fit for 55 legislative package. If the new 90% emission reduction proposal will be made binding by the next Commission, the intention would be to build on the pervious 55% target for 2030.

EU climate commissioner Wopke Hoekstra told the European Parliament yesterday that the EC has intended to start “a dialogue on the pathway to 2040”, referring to the fact that concrete proposals will need to be made by the next group of policy makers in Brussels.

According to Politico, as of 2022, the EU’s greenhouse gas emissions are 32.5% lower than in 1990.