3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

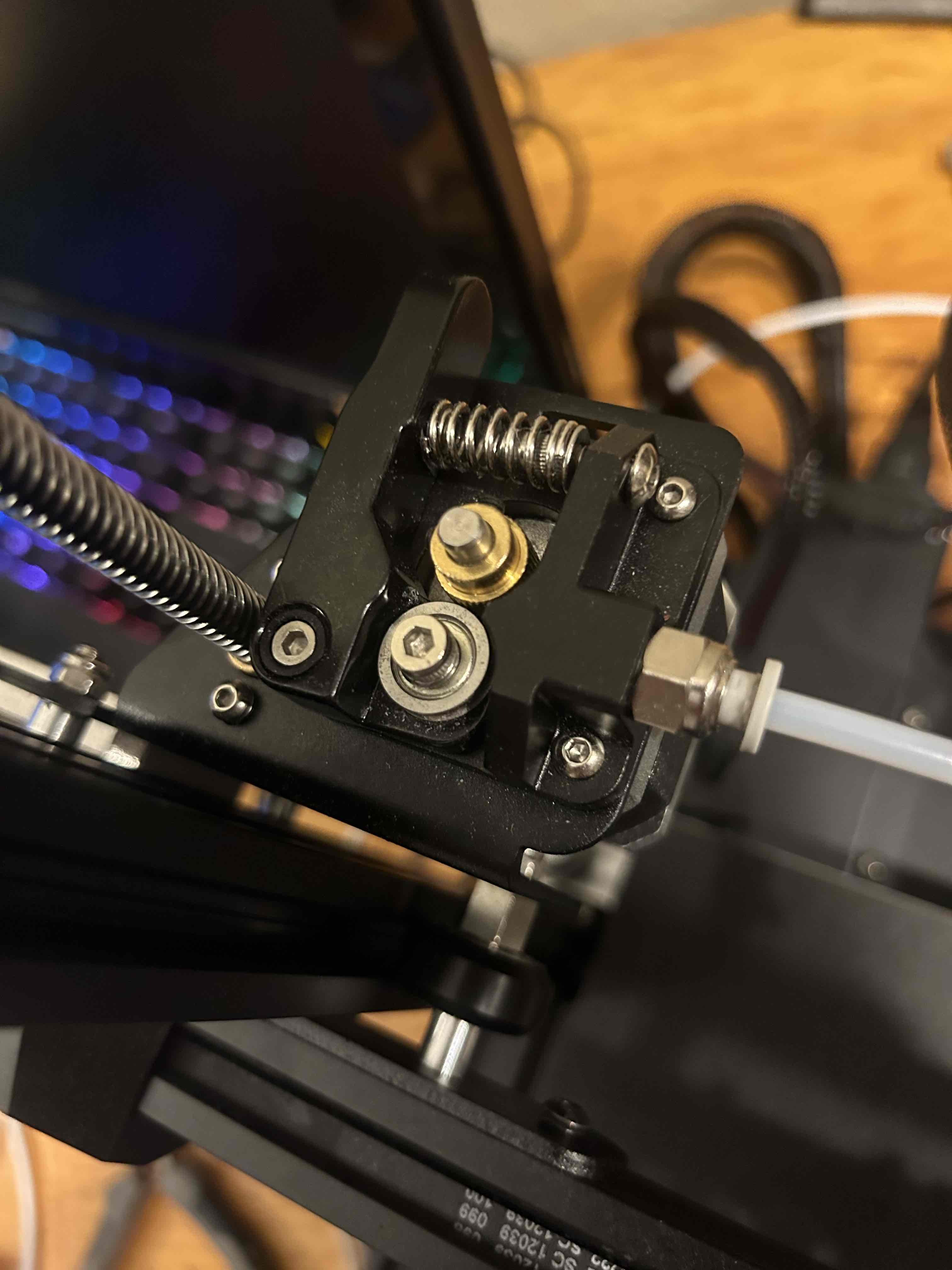

Check the screw that is imbedded in the brass gear. It holds it in place to the stepper motor it is attached to. If it is loose at all then it will produce similar results to a clog. Also be sure that the screw is aligned to the cutout on the stepper motor axel. That is what keeps it spinning. If it is tightened but not aligned then it will make that skipping sound.

Thank you! I retested and tighten the screw down way more. I’m testing now. Fingers crossed that did it

One more thing to check that caused clicking on my ender 3, the plastic retention arm the spring connects to had busted. I couldn't even tell because it was underneath the silver roller.

They make a kit for $12 on Amazon that exchanges the plastic parts for aluminum parts because apparently this failure is almost guaranteed to happen eventually.

https://youtu.be/YakBCTKhX3c This guy's choice of fashion may be questionable, but he's spot on on the problem in this video.

Here is an alternative Piped link(s):

https://piped.video/YakBCTKhX3c

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I'm open-source; check me out at GitHub.