Thanks for the input. To simplify we're going with straight edges (I think it'll look classier too) and I am going to put some dowels in for a bit of additional joinery strength. See pics attached for some drawings. Also I think technically this is just an angled bridle joint, not a half-lap bridle joint.

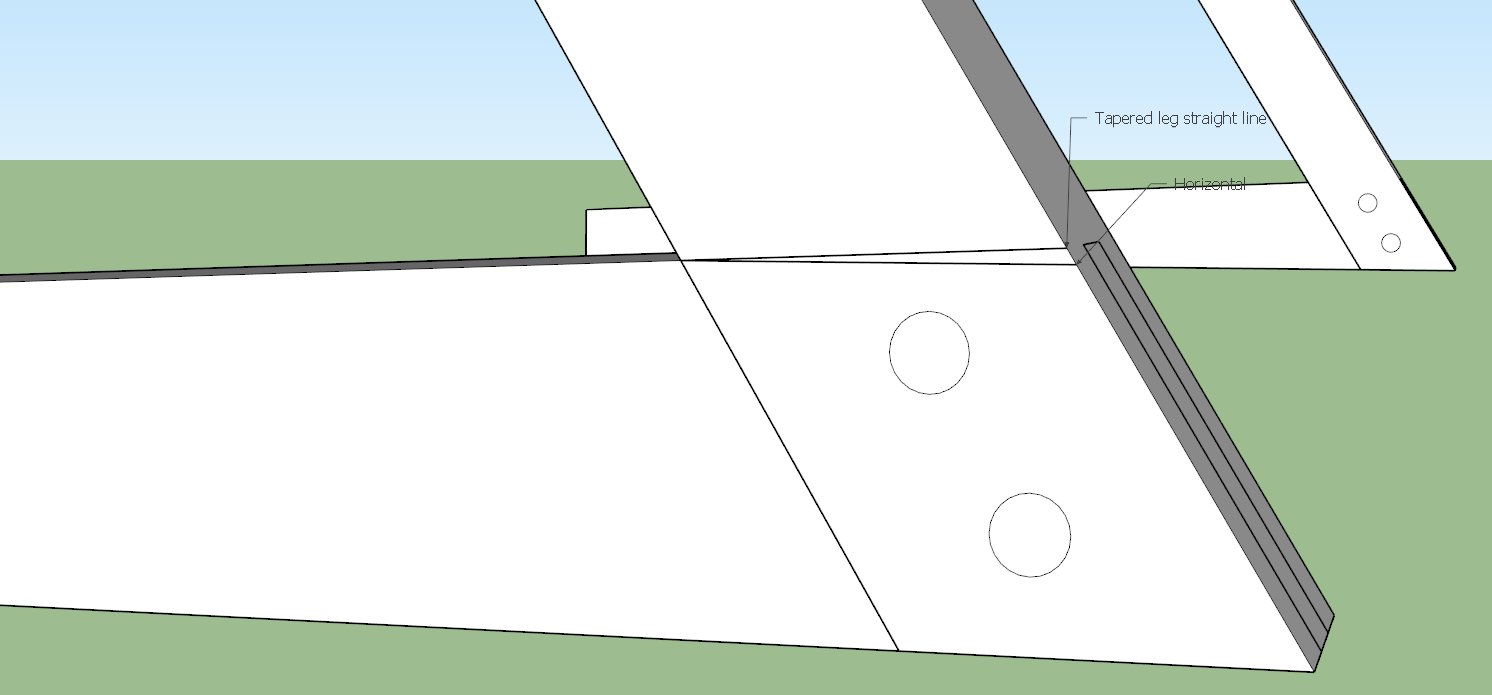

Now I have a further Q. And that is "how does one cut the inside of the outer(!!) bridle, on an angle to accurately match the taper?" (see the triangle with text labels on the drawing). The offset from horizontal is about 2.5 degrees due to the tapered nature of the horizontal legs.