3D print it or have it printed for you, https://www.printables.com/model/235677-logitech-mx-mechanical-key-caps

Rilton

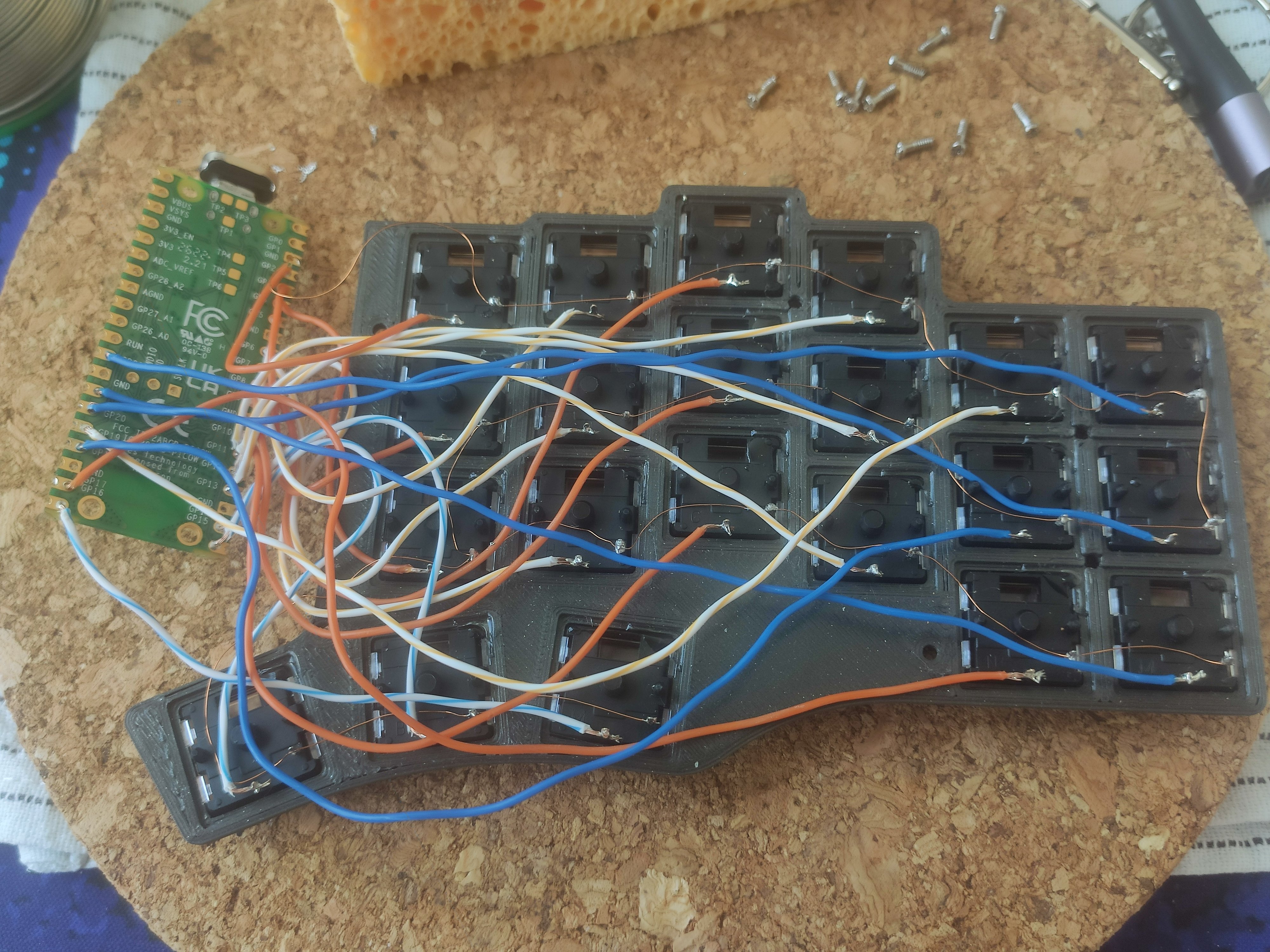

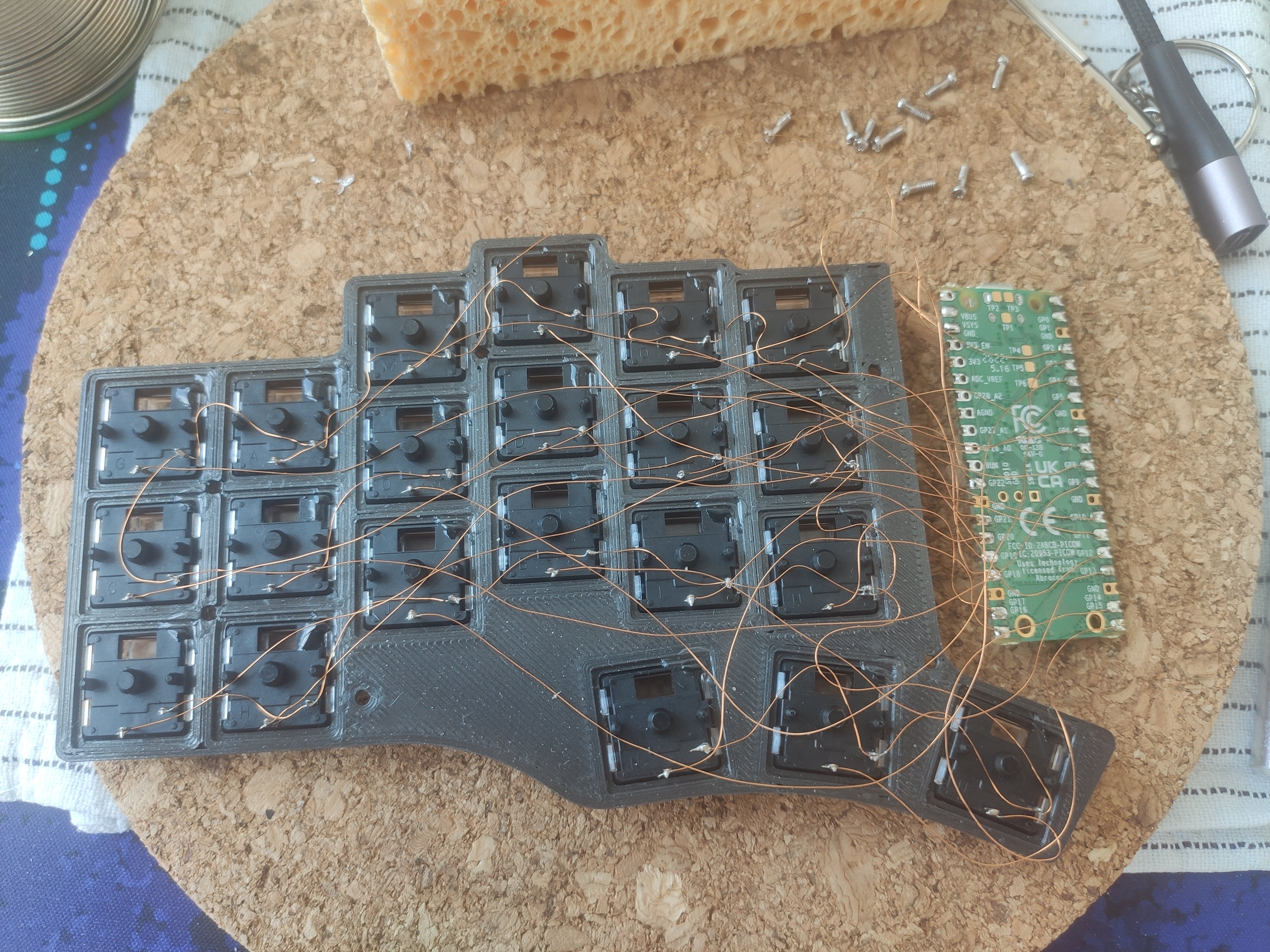

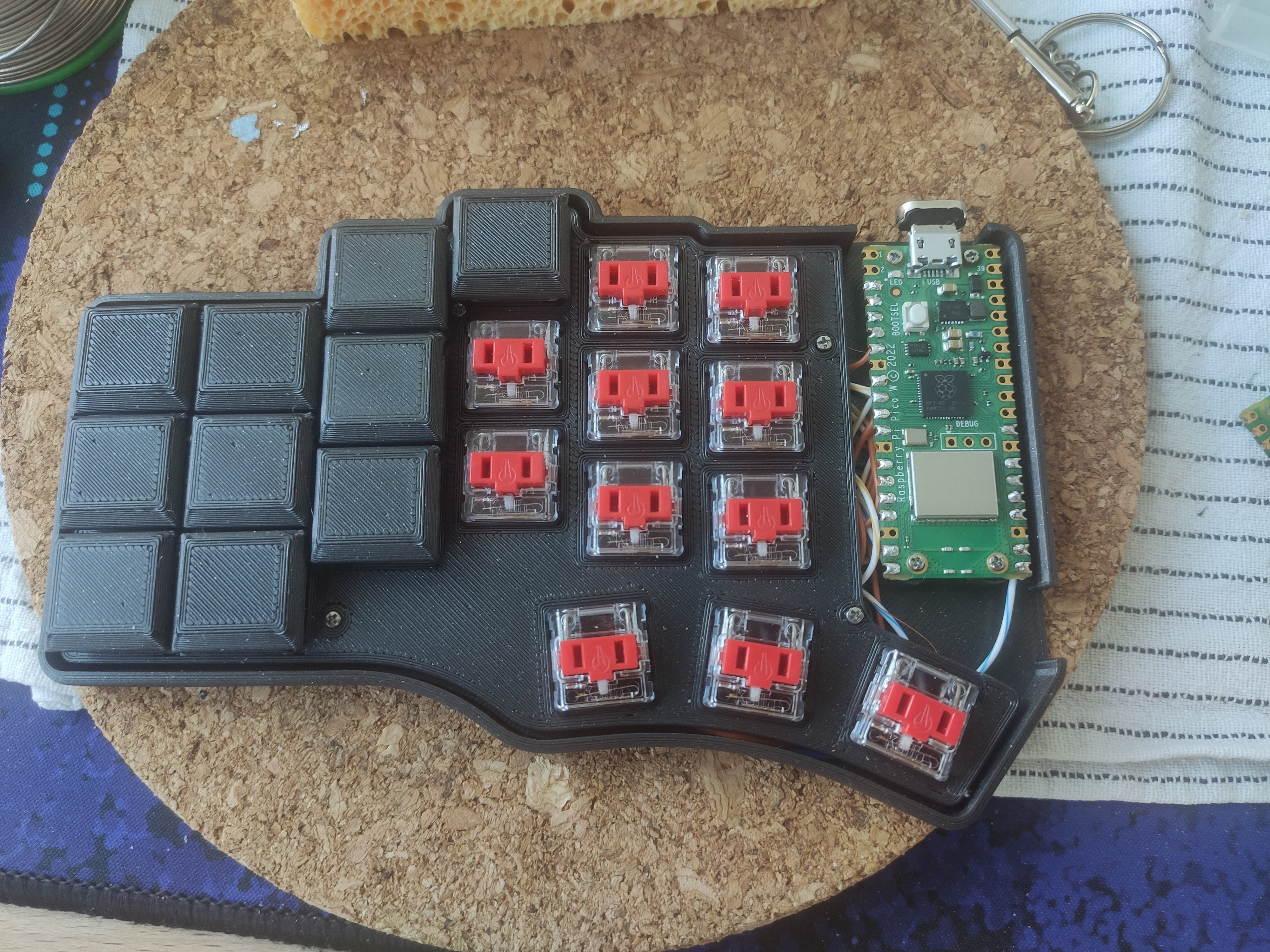

KMK is similar to QMK but it runs on python, and it being python means that nothing needs to be recompiled for it to apply your changes. The pico has circuit python running on it which acts as a removable usb drive that contain your config files. With any device that you can use to read a flash drive you can reconfigure your layers/keys with. It's quite flexible to use. Open up notepad/vim and click save, the board reboots with your changes.

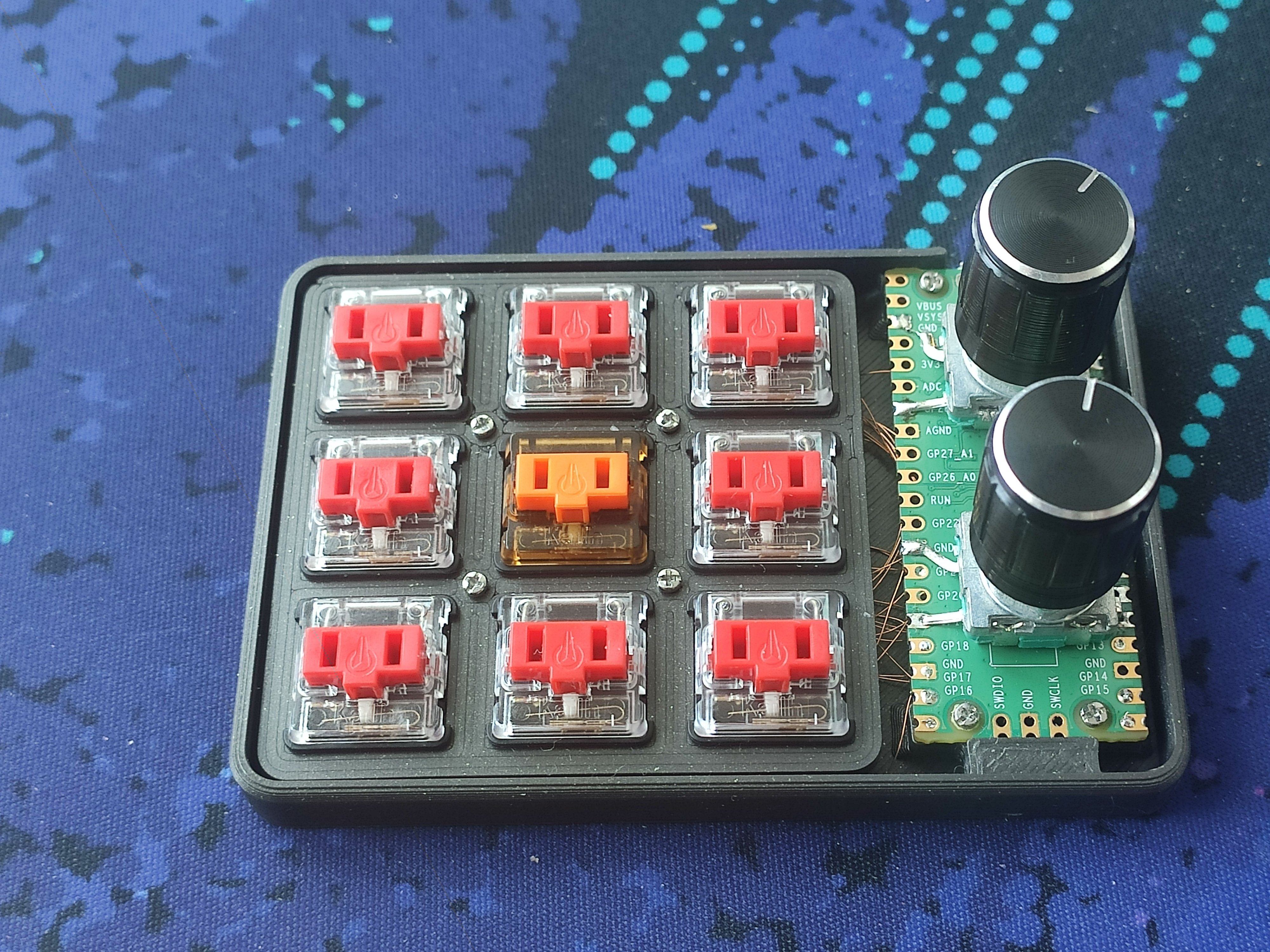

Magnetic usb quick connect. Think of the old apple magsafe connectors

I picked these keycaps because of the fast printing and prototyping. But I do see feel a slight downside to this. There are no marker keys so my finger keeps getting lost when I'm typing fast. I would like to move to better sculpted keys in the future, maybe even tilted keys too.

Thanks I had a great time building it. Now it's time to put it to the test and use it as my daily driver.

It'd be quite easy to 3d print a tilt that snaps on to the bottom and sides if you wanted one for the piantor, or any other keyboard tbh. I'm coming over from a black widow elite razor keyboard and this low profile makes it so that I don't need a wrist cushion. I have no experience with the moonlander unfortunately.

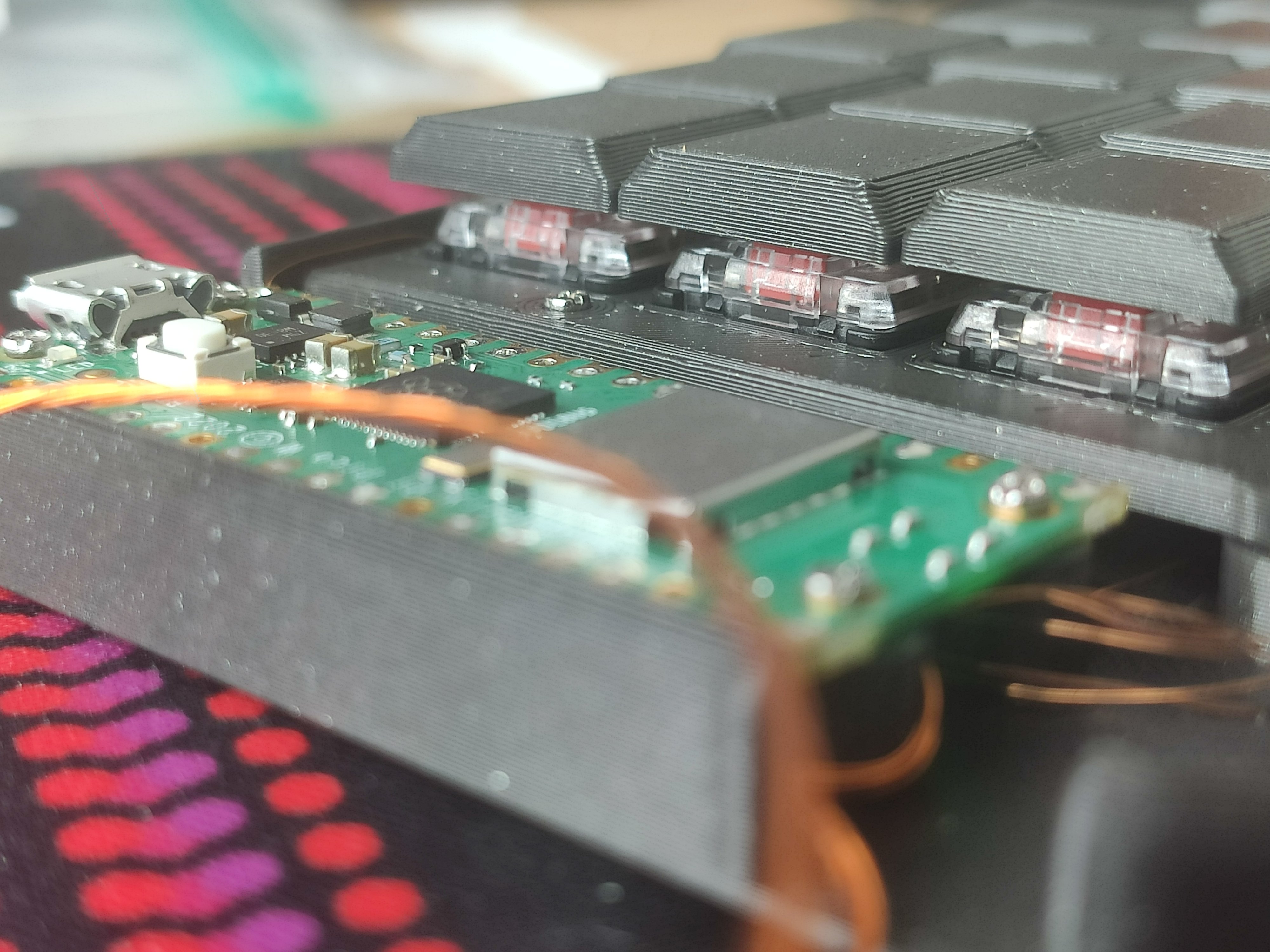

Everything about it is open source, the only limitation is microcontrollers that support circuitpython. Most of the controllers that work with QMK also work with KMK. The pi pico for example that's used is much cheaper than the typical arduino pro mini, and comes with more storage and i/o pins.