Do you have a multimeter? I'm not familiar with your printer, but is it possible to disconnect the heater wires from the motherboard and check the resistance between them?

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

Yeah, i have ohm'ed the heater. It actually was the same resistance as the one i thought was dead... I don't remember the value (I'm at work right now)

You don't want to read the resistance of the heater. You want to find the voltage being sent to the heat cartridge.

When you're able to, disconnect your heat cart and stick your multimeter probes in the socket (or touch the top of the cable screws), and heat the nozzle. Should read 24v IIRC. Based on your answer to my other comment, my assumption is the number will not change when you turn on the heater, implying board or mosfet failure.

You want to do both

Home, and done some measuring.

- measurement:

Just started the printer: 1,24 VAC

Preheating the nozzle: 0,00 VAC

After error beep: 1,24 VAC - measurement:

Just started the printer: 1,57 VAC

Preheating the nozzle: 0,00 VAC

After error beep: 1,57 VAC

Old heater: 13,6 Ohm

New heater: 14,6 Ohm

So, no power to the nozzle heater. Now, how to verify the mosfet?

I will measure the voltage when I get back home later today. It probably will show no volts, so which board is defect? The little one in the hotend or the board on the other side of the USB-C cable? How to verify the mosfet?

so which board is defect? The little one in the hotend or the board on the other side of the USB-C cable?

My money is on the main board inside the printer. The "board" on your hotend (if it's like others) doesn't really have any computers or controllers on it, it's more like a fancy cable connector between the main board and those components.

If you test the voltage and get nothing, it's either the main board or the mosfet for the heater. If you test it and it gives you a stable 24v, the problem lies somewhere between the main board and the heat cartridge (cable, connector, the hotend board, cartridge itself).

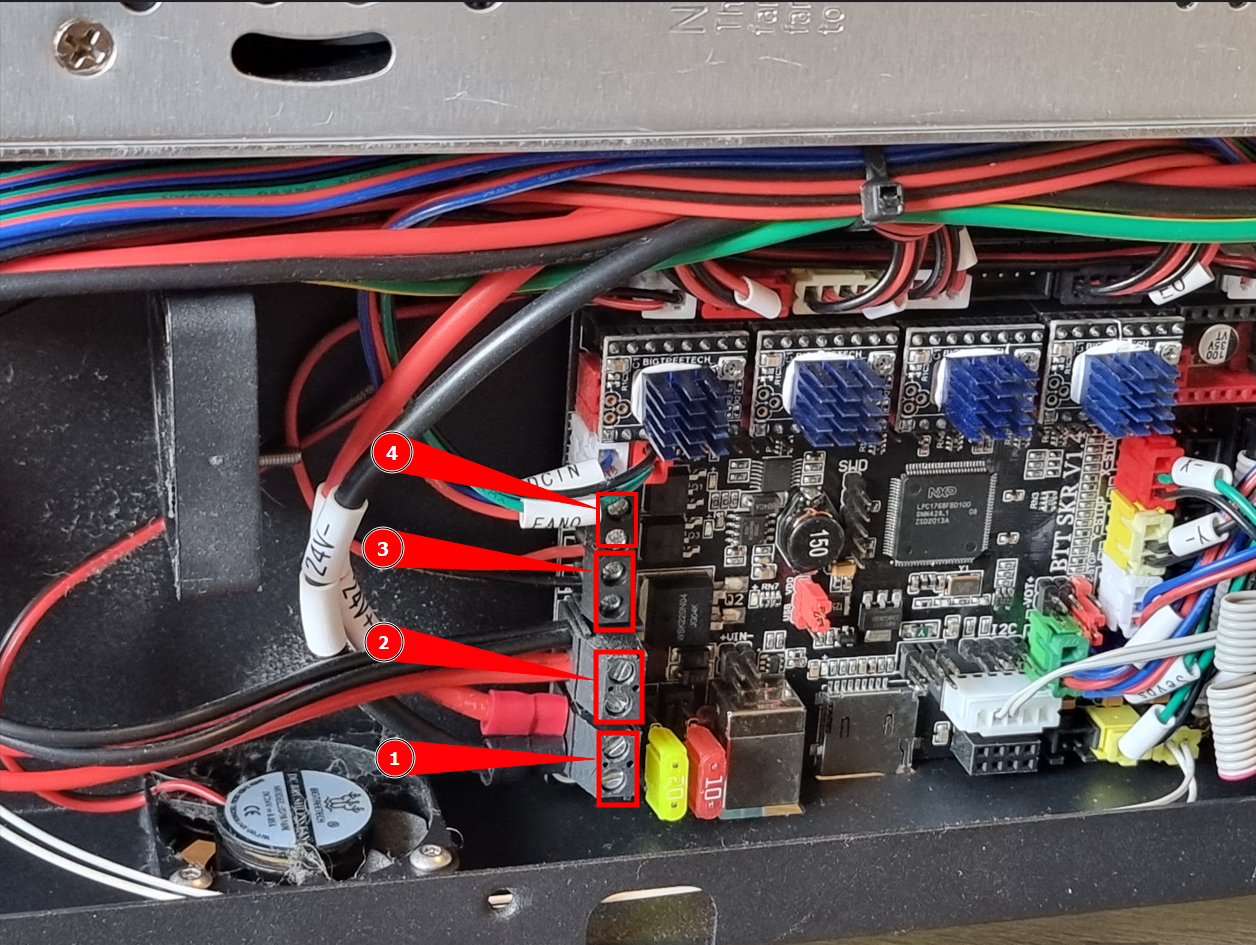

Can't say for sure without looking up your board and pin out chart but I'm pretty confident you're probing one of these guys

- Power from PDU = OK

- Power to bed heater = OK

- Looks like power to the nozzle heater = same results as when checking volts directly on the hotend.

- Empty

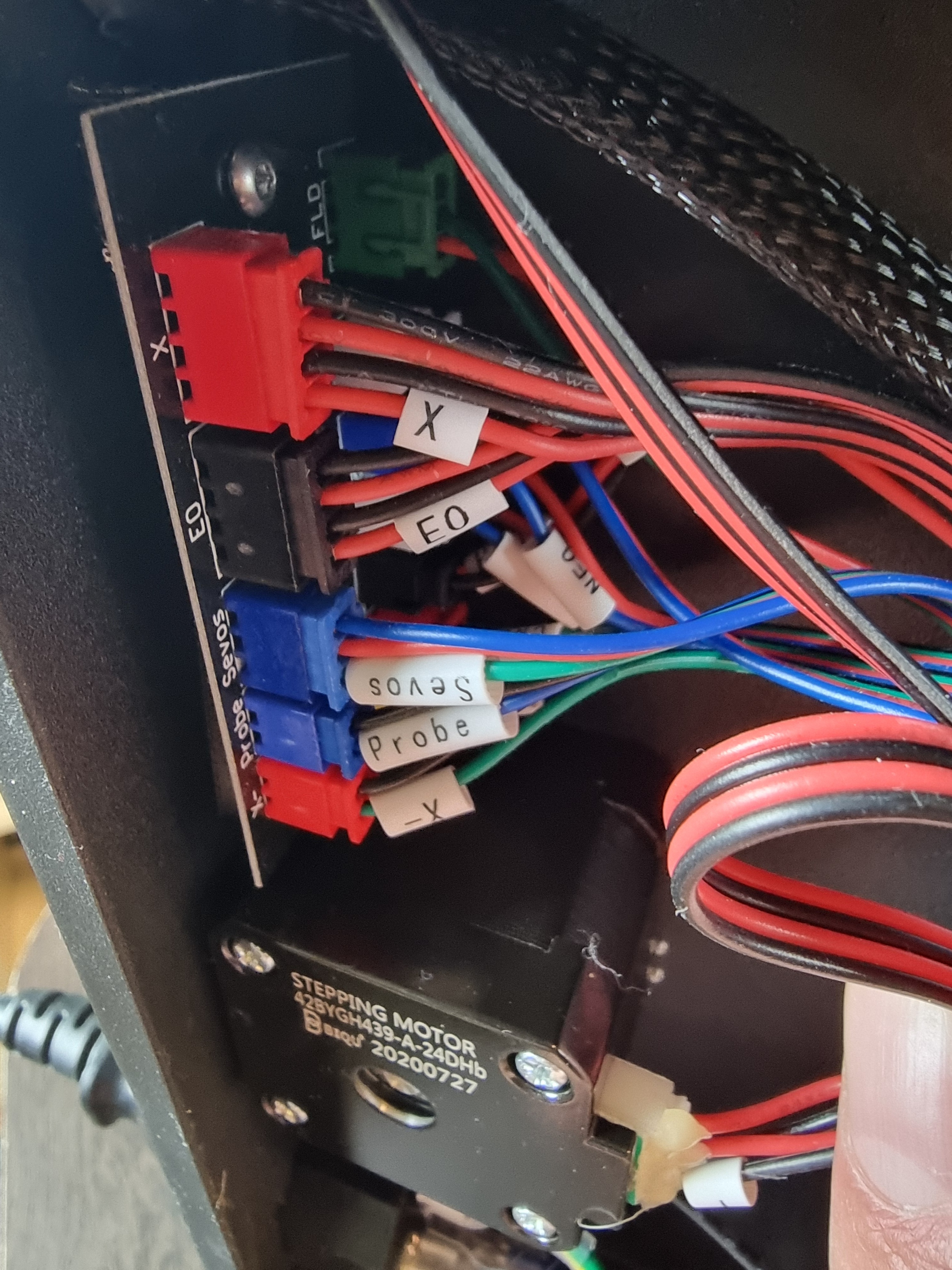

#3 goes up to a board back on the printer. This board has multiple outlets, and one USB-C that goes up to the hotend.

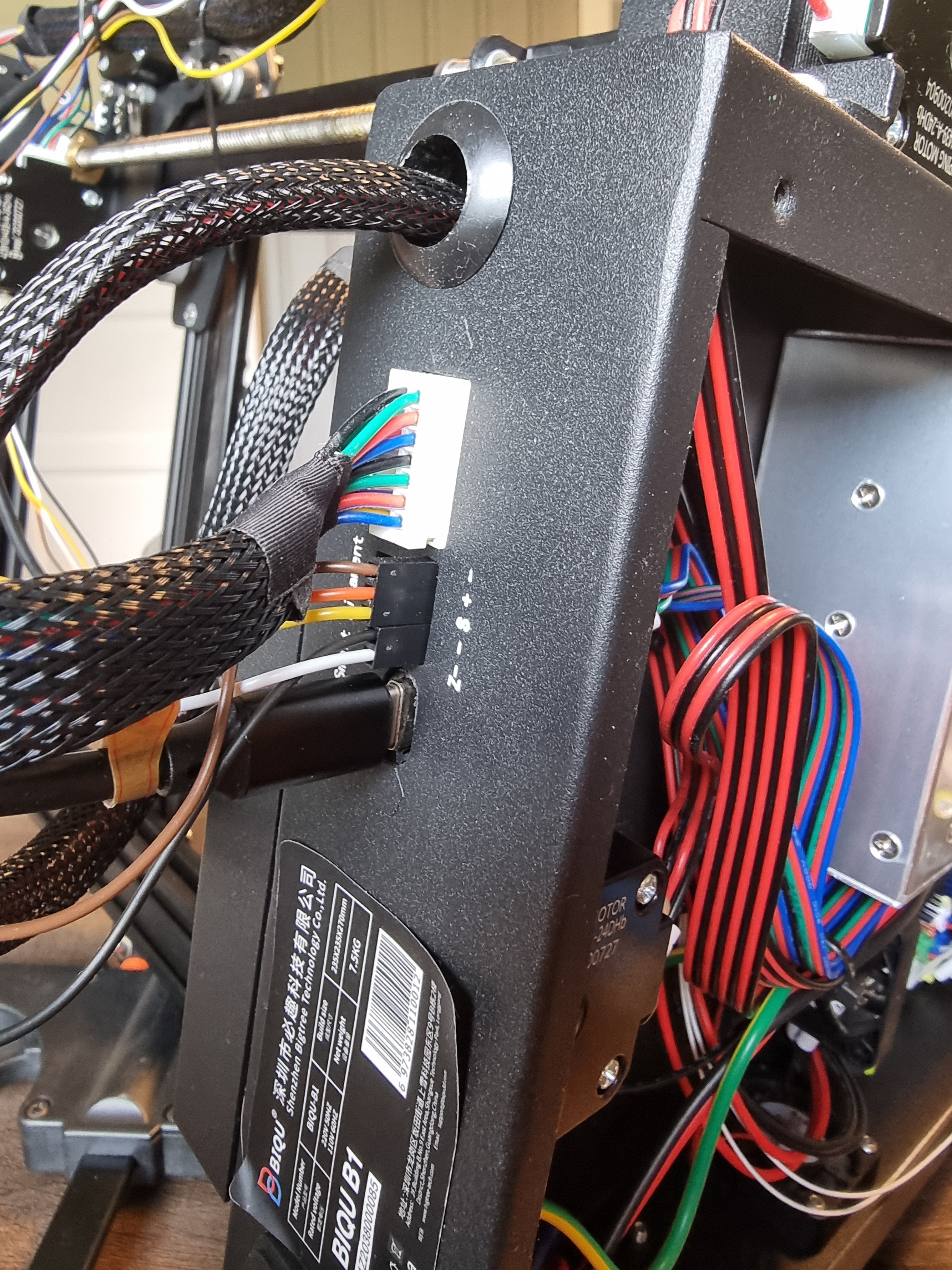

This is the board that has a USB-C on the outside for the hotend

The outside view

So that little board is simply connecting all the cables from the main board into one cable (the USB C cable). If you're getting nothing from the main board, either the board itself or the mosfet for the heater is dying.

Honestly, I don't know how you'd go about testing board vs mosfet, if it were me I'd just replace the board, but somebody else might be able to tell you if there's a better route to take

Yes, that little board connects many of the cables from the main board to one USB-C, the the black and the white connectors. The USB-C is the only one going to the hotend.

Anways, thank you, kind internet stranger, for trying to help me out with this. Looks like I'm gonna have to replace the mainboard.

Our hobby survives on the backbone of kind internet strangers, to deny your call is to deny yourself.

I don't know your printer's configuration, but assuming a pretty standard setup (single extruder, single X and Y steppers, single or dual z) I can recommend the SKR MINI 3.0. It's a gem to handle, documentation and firmware are readily available on their GitHub, and best of all, they're cheap and easy to source (assuming you're in the US).

While you're looking in to changing your main board, may I suggest you take a peek at Klipper? It's phenomenally worth the effort it takes to set up, and you're already going to be doing a big amount of the same legwork if you're getting a different main board than stock.

Yeah, it's a pretty standard setup. The previous owner put a BLTouch on the printer but never got it to work. I've had the printer for about 2 weeks and was about to figure this ABL out, but it misses the ABL option in the menu.

I'm pretty new in the 3D print business and know nothing about flashing, compiling, and all the options you can do. You recommend the SKR MINI 3.0, and i didn't know i could change the mobo to other than the original SKR V1.4. What are the benefits of changing to the SKR MINI? And, no, I'm not in the US. But I'll find it here in Norway..

And Klipper? Not heard of that either, but a fast youtube peek tells me that this too might be interesting..

and i didn't know i could change the mobo to other than the original

That's what's great about (most) printers, you can do whatever you want with them 😁

about to figure this ABL out, but it misses the ABL option in the menu.

That's because you're using the stock firmware, which was not compiled with the bltouch in mind. If you want to get that working, you'd have to flash a different firmware, at which point I'd highly recommend Klipper, maybe I'm just bad at using Marlin (the other popular 3d printing firmware) but compiling firmware for it was a million times more difficult than getting klipper working

SKR MINI V3 and a Rasperry Pi 4 (for Klipper) is ordered and in the mail..

Shit, what have i done. Haha

Shit, what have i done.

You've added another notch to you nerd belt!

That's the exact setup I've got. Let me know if you have any questions or issues getting things set up. Once you have it figured out you'll wonder why anyone uses marlin.. there's just so much available. With marlin, literally everything is baked directly into the firmware, and unless you compiled it yourself or dug through the code you've got no idea what's going on with the printer. Set up a retraction tower? Better hope it was set up right because marlin won't tell you current retract settings. Leveled your bed? Better hope that the numbers stick and the mesh is actually applied to prints.

With Klipper, not only is all of that easily configurable by editing a text file, all of that information is available directly in the GUI. Want your printer to do something else at the start of every print? Just change your start up macro. Realize that you set the wrong retract distance in your slicer? Just change the setting in the GUI. Start a print job with 5 models and one of them starts to fail? Don't cancel the whole print, just the part that's failing.

These are just off the top of my head improvements and there's literally dozens if not hundreds more. What have you done? You've elevated.

Let me know if you have any questions>

I only have questions.

First things first, i probably should get control on the cables and their markings before i take out the old mainboard.

I'll start this adventure as soon as the parts arrive. Parts are still in the mail somewhere..

Thanks for offering to help me out here.

Welcome to Biqu B1 world. Where nothing makes sense and you'll never be able to get a nice print.

Mine came with the same issue and nothing solved it. It's literally a piece of trash in my room. Saving for a Bambu. btw I have a Elegoo for years and it's perfecr

out of curiosity, why would you not have gone with an Ender 3 over this non-brand thing? Or if you have Bambu money, that or another quality brand? It sounds like a recipe for pain and it's not cheaper than the super well (community) supported Enders.

I'm a totally noob in the 3D printing scene. My brother has a Biqu B1 and I've printed some small things on his printer. Found a used Biqu B1 for sale for about $80. Yeah, not good research from my side... But, I've printed a well printed fucktopus before it died...

Honestly $80 sounds like an absolute bargain, you straight up can't build one yourself for that price, a mainboard and like 2-3 steppers would go over that and everything I've seen about that printer says it's a very capable, budget friendly option. It looks like that's using a btt mainboard which I totally swear by, straight up shorted a fan header on an octopus pro and it's still chugging along just fine, anecdotally they're pretty hard to kill.

I'd totally check your wiring before replacing a board, a break or bad crimp could totally be your culprit here, and those are a heck of a lot less work to remedy, thermal protection does totally get tripped if there's an intermittent fault with the thermistor (including cabling), I had it happen on a prusa where it'd kick out but not have anything obvious temp wise on the display, only noticeable in a temp plot.

The thermistor temperature reacts to me touching the thermistor-end. This shows in the display- So i believe this is not the problem here..

Fair, a wire break can be annoying though, often they're intermittent, and the display often doesn't respond fast enough to show that, but thermal protection will.

I'd totally consider taking a look at the connectors to the board for the heater cartridge, see if there's good contact being made, check for any signs of things like scorching check end-end continuity. Looking at the schematics for that mainboard Btt skr 1.4 it looks like there are LEDs on all of the MOSFETs, it will give you a visual indicator of the board state, to help narrow down your troubleshooting.

Thanks for the links. Can't see any scorching, and everything I've measured seems OK. If there are LED's on the mainboard, i don't know how to light them. As of now there are no lights on the motherboard, but everything beyond that heater works..

$80 makes it reasonable. At normal MSRP... Ender.

Good luck and make upgrades slowly and as needed.

Haha, slowly it goes.. Changing the SKR v1.4 to a SKR MINI V3 isn't straight forward on the Biqu B1.

Because I'm dumb. I don't have bambu money and a couple of years ago I didn't even knew about it. I read somewhere that biqu b1 was better and had less problems than the Ender and was noob enough to fall for it. I'm used to resin printer so I didn't knew enough about fdm and just went with biqu. Horrible decision

It's not easy trying to research which 3d printer to buy, there is more click bait and marketing than impartial reviews out there, and search engines tend to promote the garbage. And without a lot of 3d printing experience, it can be difficult to know if a "review" is paid for by the printer's manufacturer, or just trying to trick you into clicking their affiliate links. There are also no consistently good brands if you're looking for a cheap printer, pretty much all of them have produced a few good printers and others that have more flaws. For example old Ender 3 and Ender 3 Pro were very good at the time, and Creality built up a lot of brand recognition, but then they switched to low quality components and seemingly stopped doing quality control and made a bunch of crap. Now it might be turning around again, as Creality's latest printers are starting to look decent again, although perhaps a little overpriced.

Personally I use this spreadsheet to compare pros and cons of budget printers. It's maintained by a group of users at a 3d printing discord server, and while one cannot know for sure none of them have any ties for example to Sovol (the most recommended budget brand currently), they've seemed quite impartial to me so far.

That sucks. I have no clue about 3D printers and did no research before buying this one used. Worked OK for about 6 days.... Well 80 bucks...

You can get a new board for <$50 (you don't need the same board that's in the printer), spend an hour or two learning how to move the cables from the old to the new, and still have a pretty good deal

I would 100% buy replacement parts IF i knew how to replace them, but to be honestbif I try I'll probably end up with a bunch of scrap. At peast the trash print some ugly things

What issues are you having? I'm sure we can help you get it figured out

Nahh, just take parts out and lay every part side by side, and just put them back in reverse order.. And, take some pictures underway of where all the connectors are connected. You can do this. Hell. i don't know what I'm doing and I'm gonna at least try...

Just need to verify which board needs to be replaced..

Make sure the wires to the hot end actually trace back into the main board. And the mosfet is fine.

It's just USB-C cable up to the hotend. Not sure how to check the mosfet..

I can se that the thermistor works because it changes values in the display when touching the thermistor-end.

Good information. You can probably remove thermistor from possible cause, but to be sure, you can tape the thermistor to your heat bed, and heat to a high temp, make sure that the "nozzle" temp is close to the bed temp

What is the behavior when you hear the nozzle? Does it immediately give error, or does it take some time? If it takes some time, is the temp changing on the nozzle at all, or it stays the same until error?

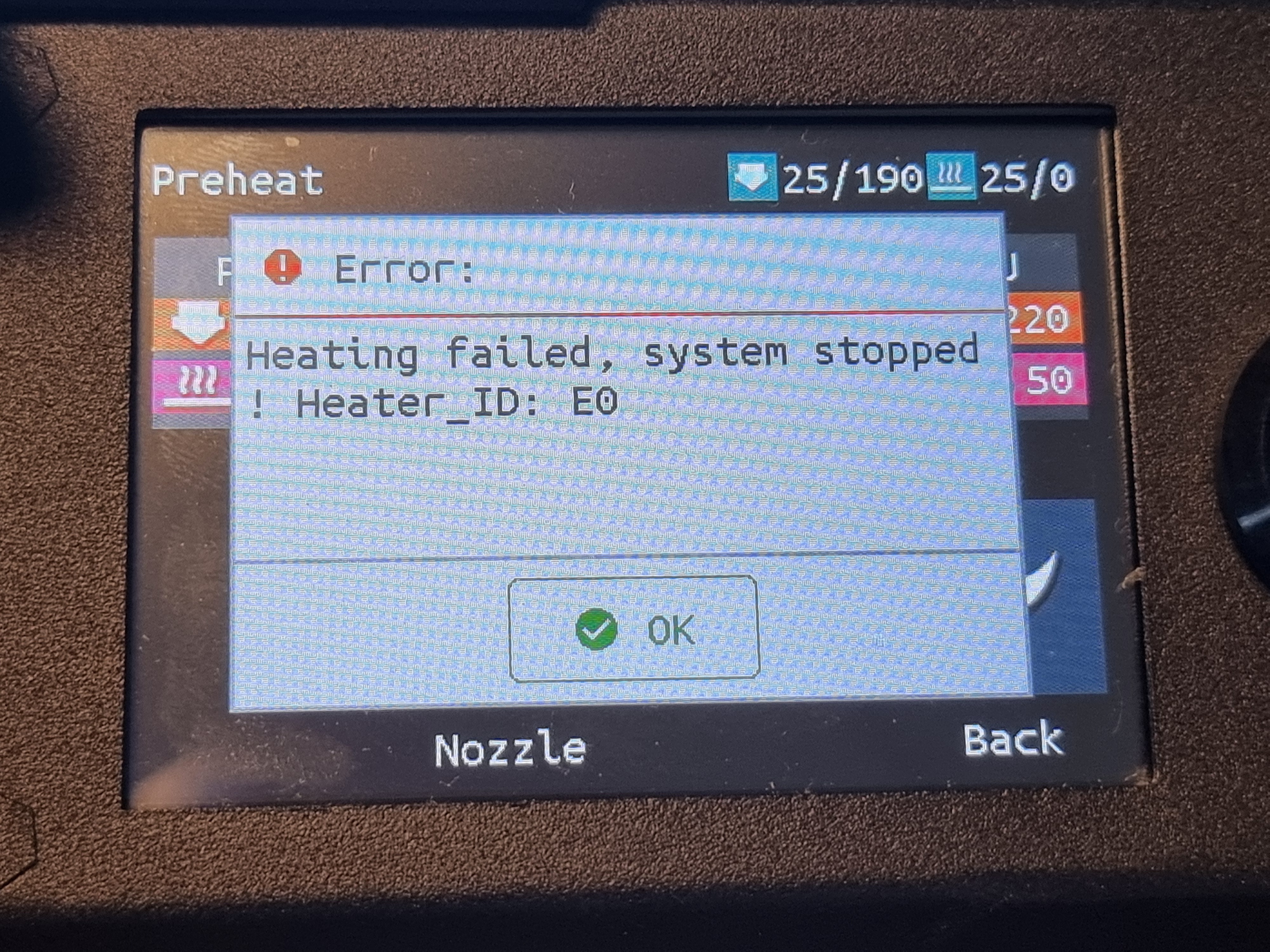

When starting the preheat both the bed and the nozzle temperature starts at about 25c. There is no heating at all. The printer takes about 10-15 sec to conclude with the error message.