A mention in the comments of that EDC knife recommendation thread from a few days ago reminded me that, yes, of course I have one of these in my collection. And if you think I've written a volume so far about knives, we haven't even gotten into the multi-tools yet. Oh boy, hang on to your tailfeathers.

There is a spectrum for these types of things. At the one end you have knives that might have an extra function or two tacked on -- a glass breaker or bottle opener are the perfunctory and perennial favorites to make a knife "multifunctional" so you can put an extra bullet point on its box. Then at the other are tools that might only just so happen to contain a knife blade. (Or all the way off the far end, multi-tools that manage not to include a knife at all, like the Leatherman PS.) Squarely in the middle of this gradient lies the traditional Swiss Army Knife.

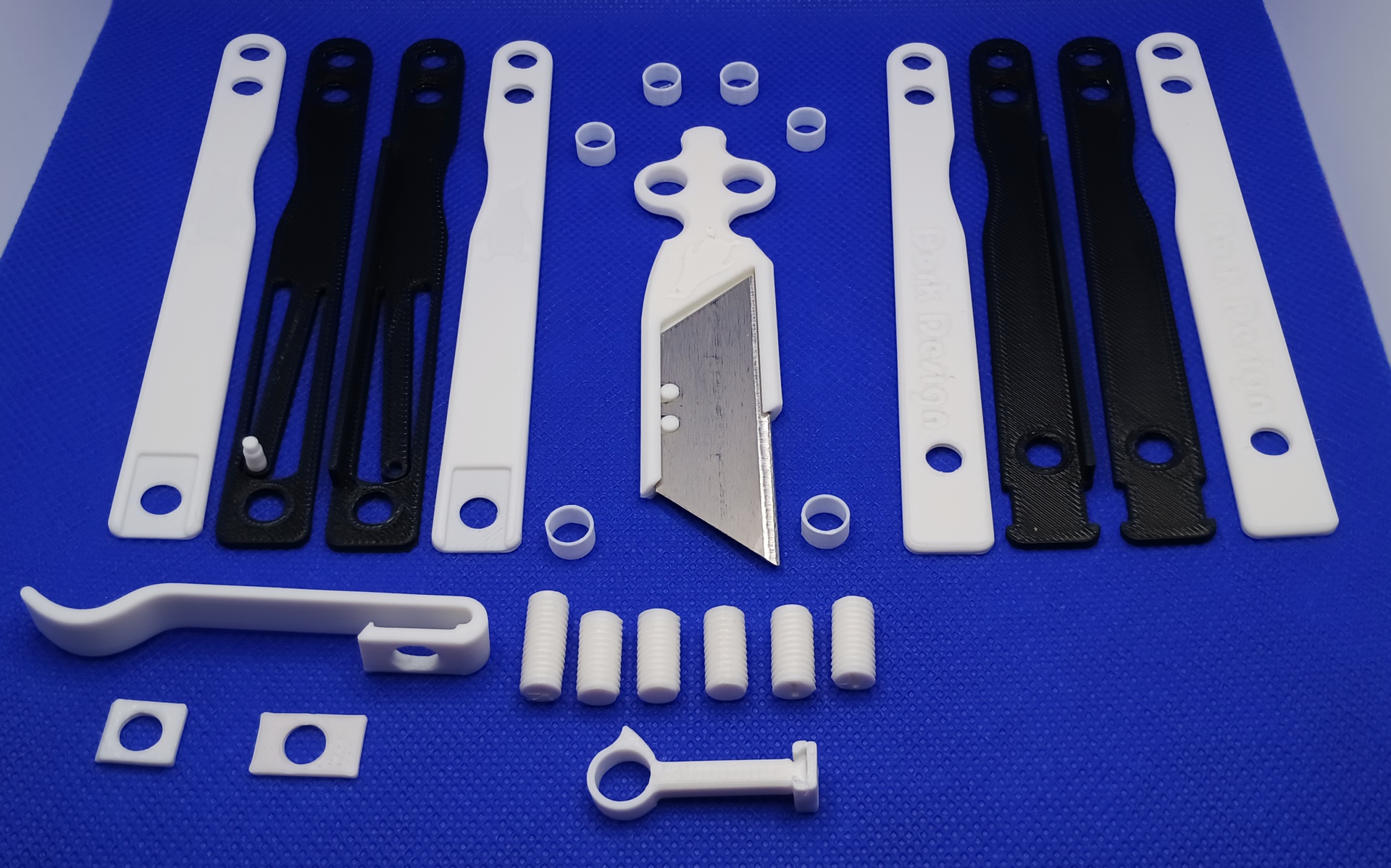

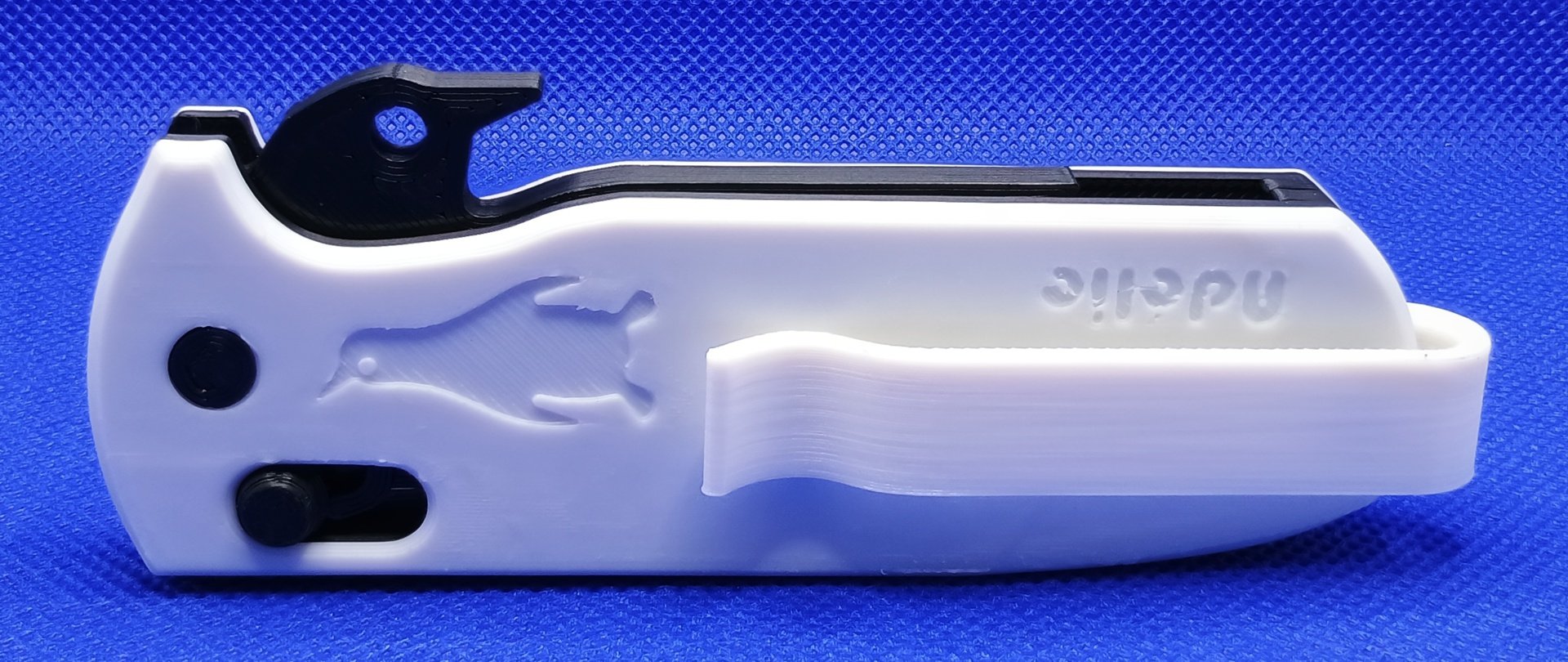

The Select Fire is firmly on the near end of that particular spectrum. It's clearly built around a dedicated pocket knife mechanism at its core. Knife first, tool second. This is opposed to stuff like classic Leatherman tools that are a knife second, tool first.

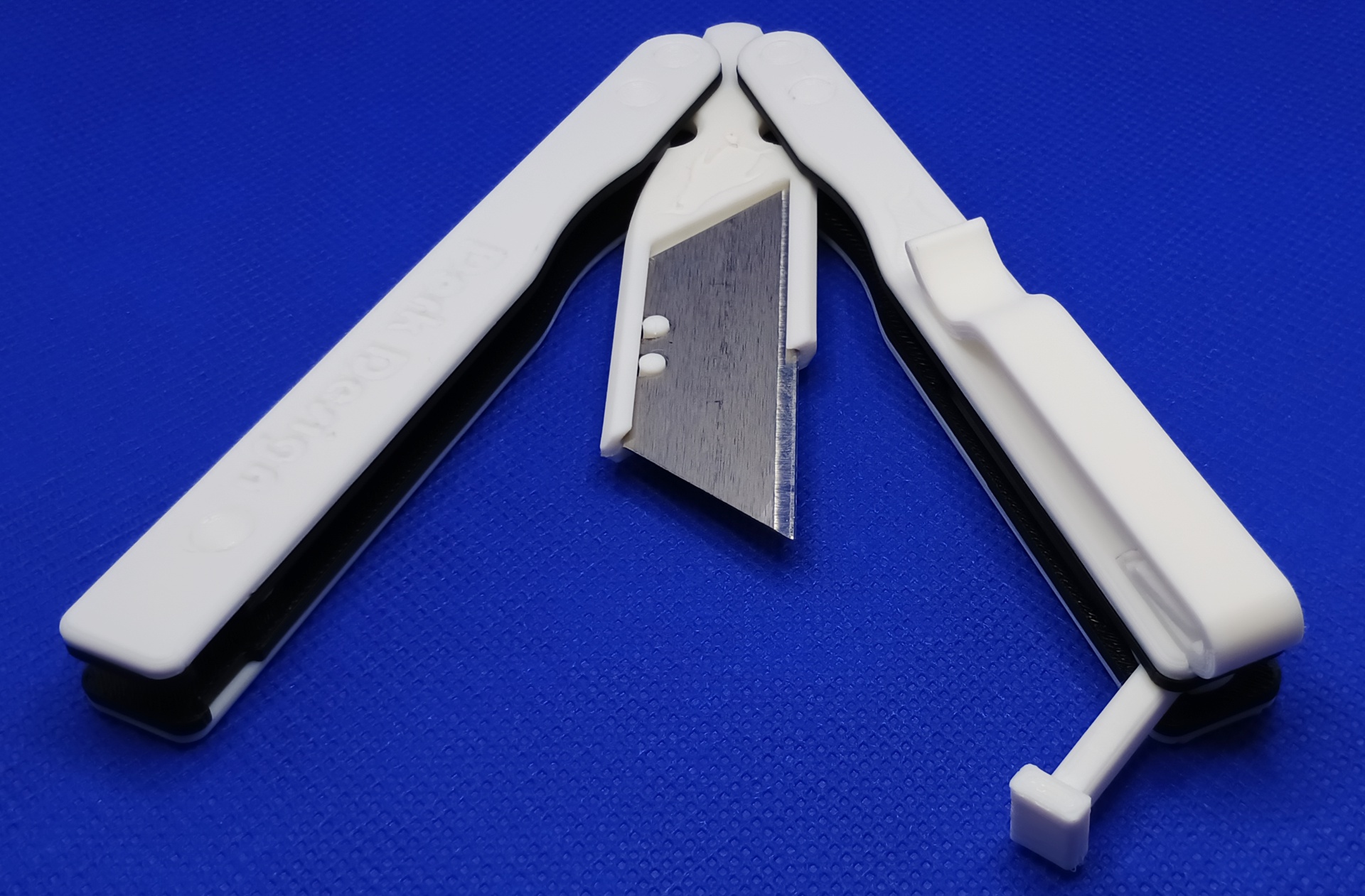

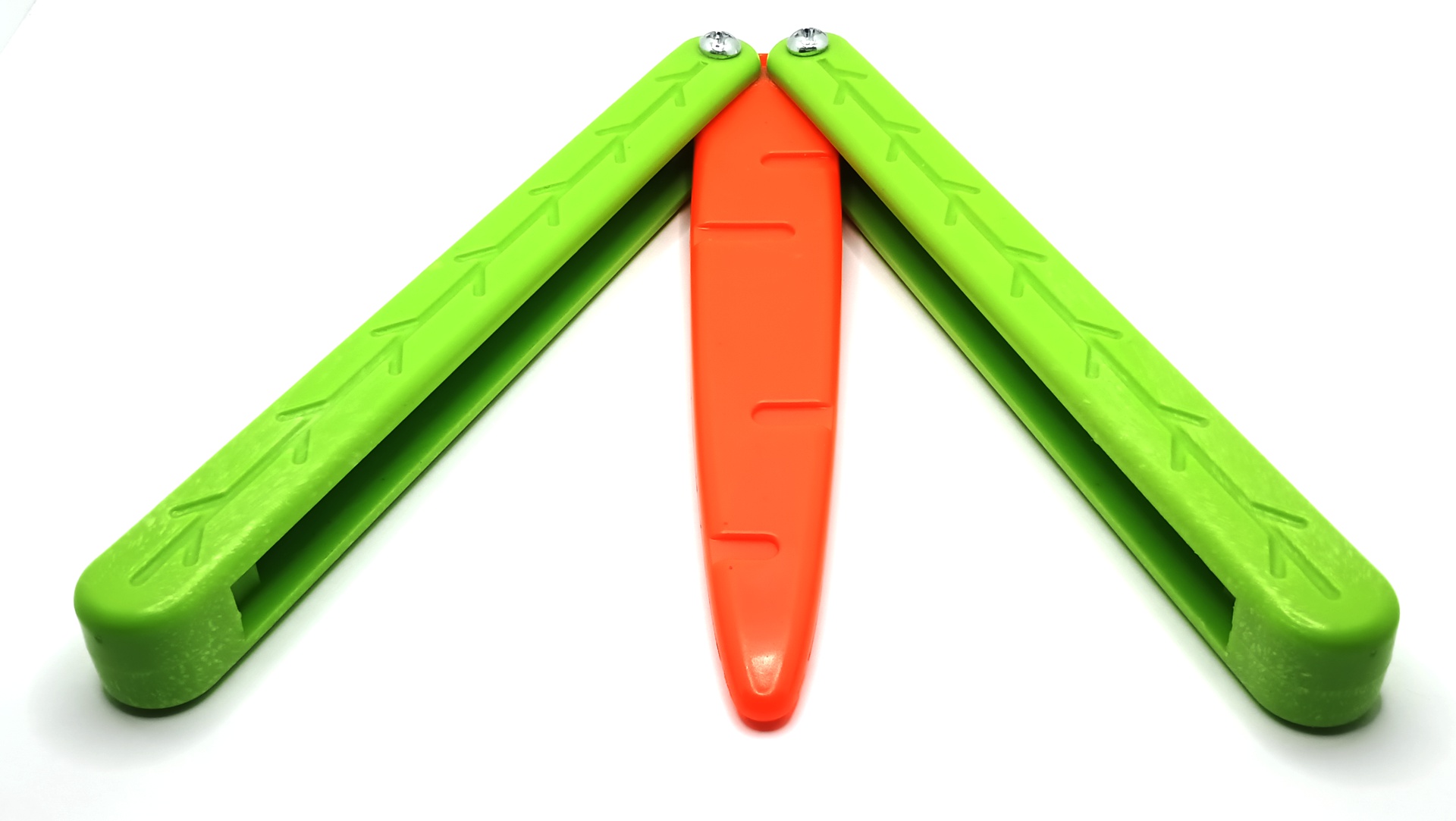

But in addition to the obligatory cutout on the back of the handle that acts as a bottle opener, it also has a fold-out tail...

...That accepts standard 1/4" hex drive screwdriver tips.

I can get behind this sort of thing. Lots of knives and multi-tools have some manner of screwdriver capability built in, but the way this is done I think is the superior strategy. This is unlike the Swiss Army approach where you get a middling and, frankly, low quality screwdriver point or two that can't be readily replaced or almost as bad, the Leatherman approach that uses proprietary (and expensive) flattened bits. Instead, with the Select Fire you can chunk any old commodity tip in there to either replace a worn out one or adapt your knife to whatever types of more specialized fastener head you might encounter regularly.

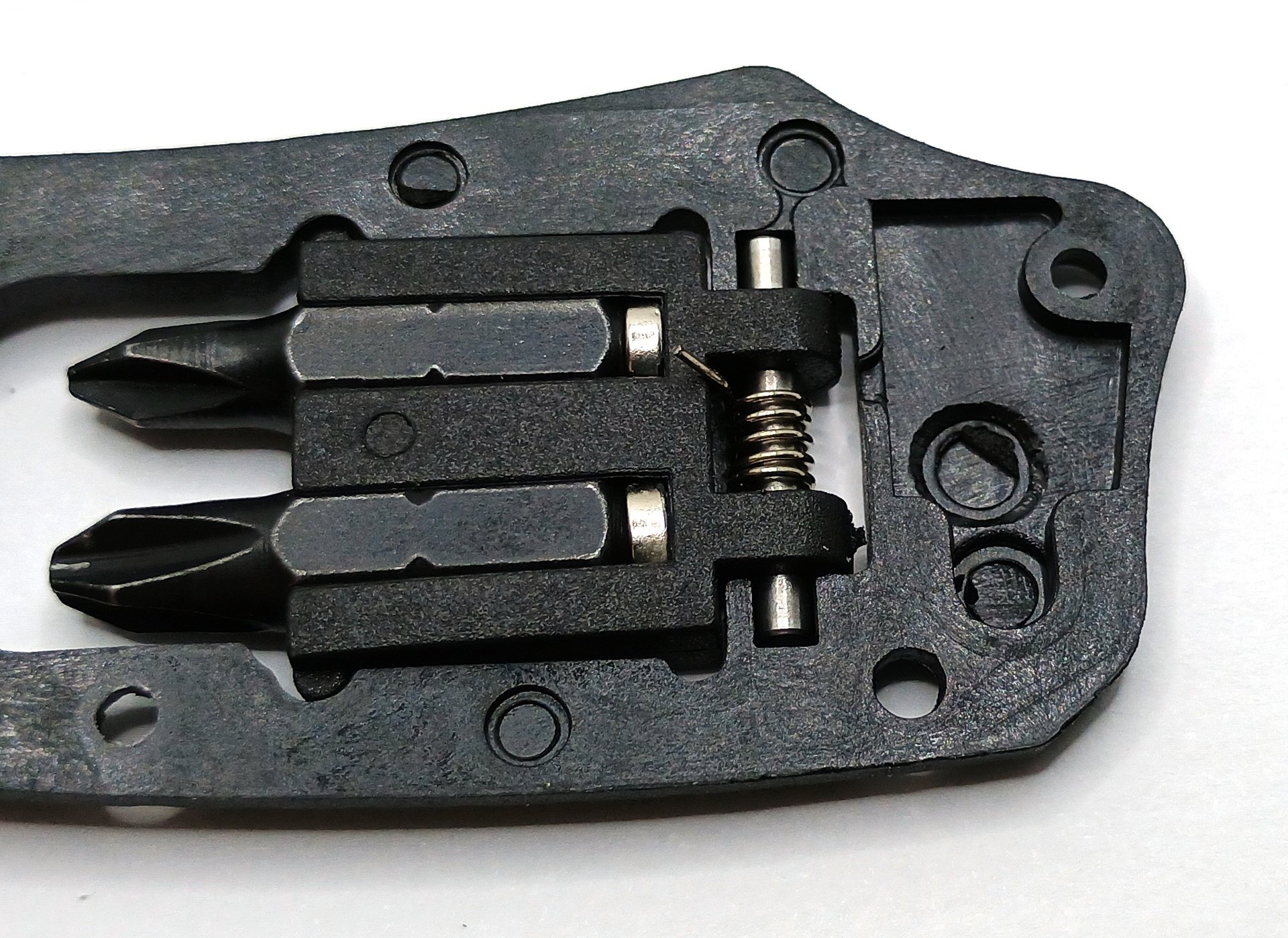

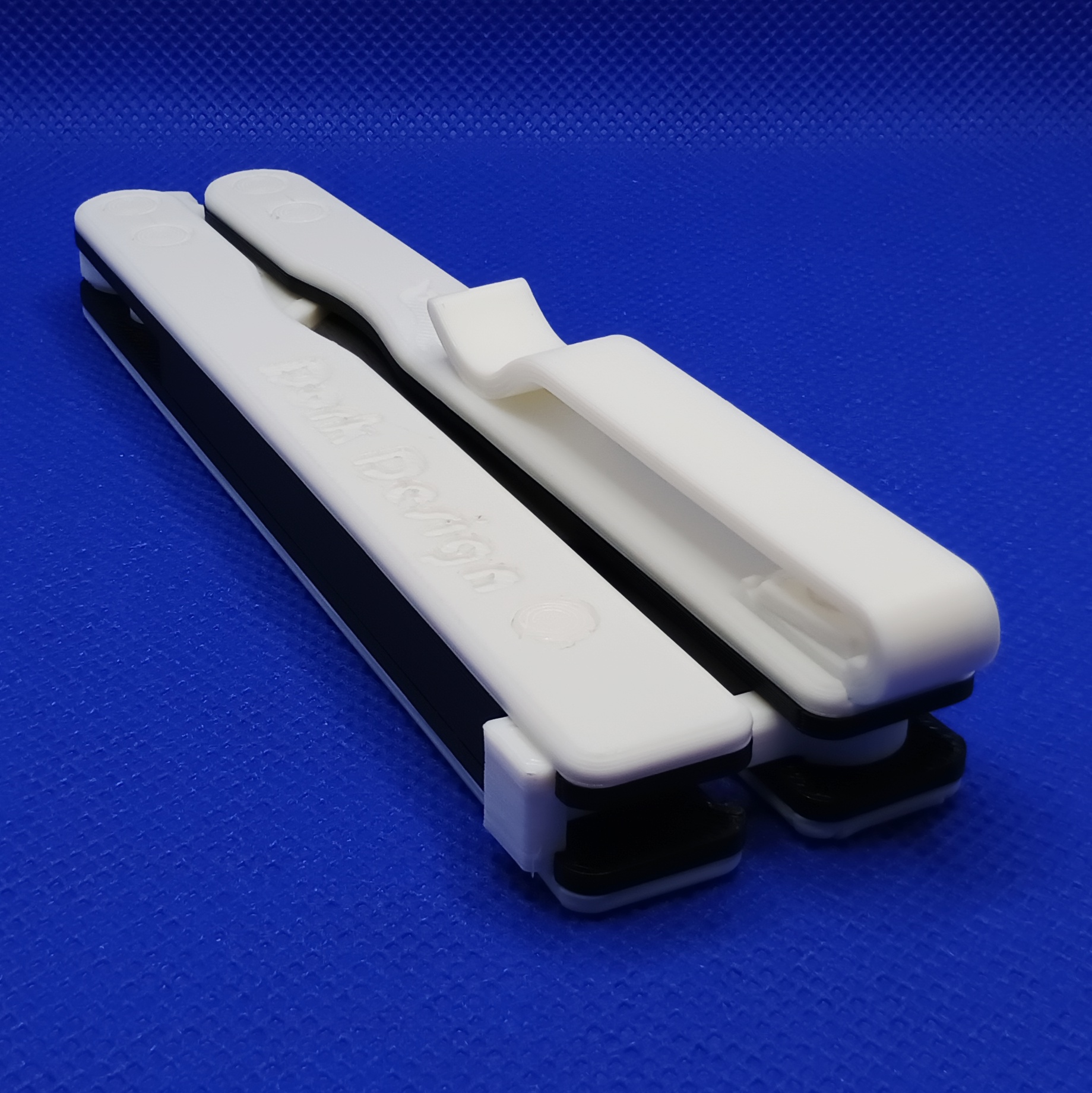

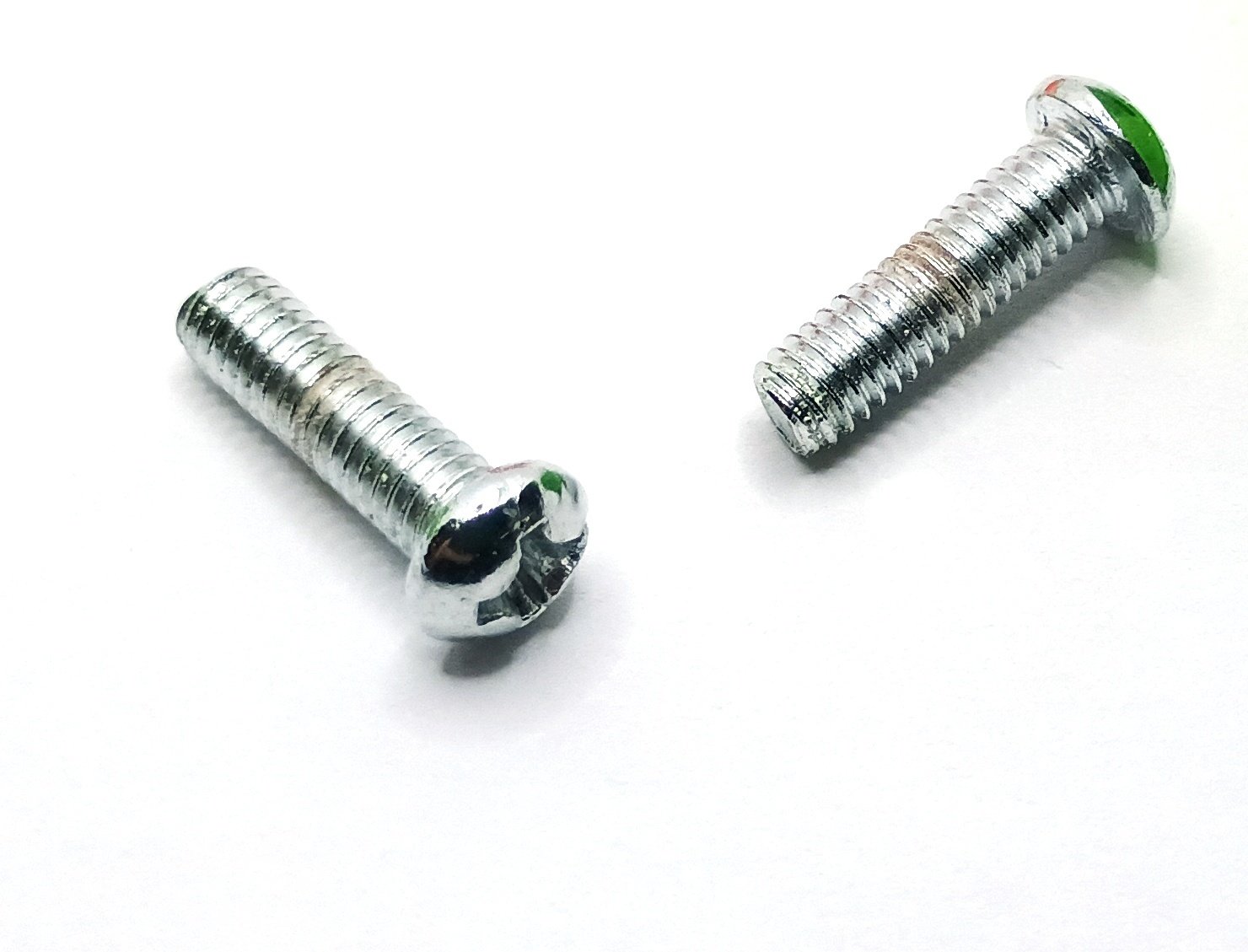

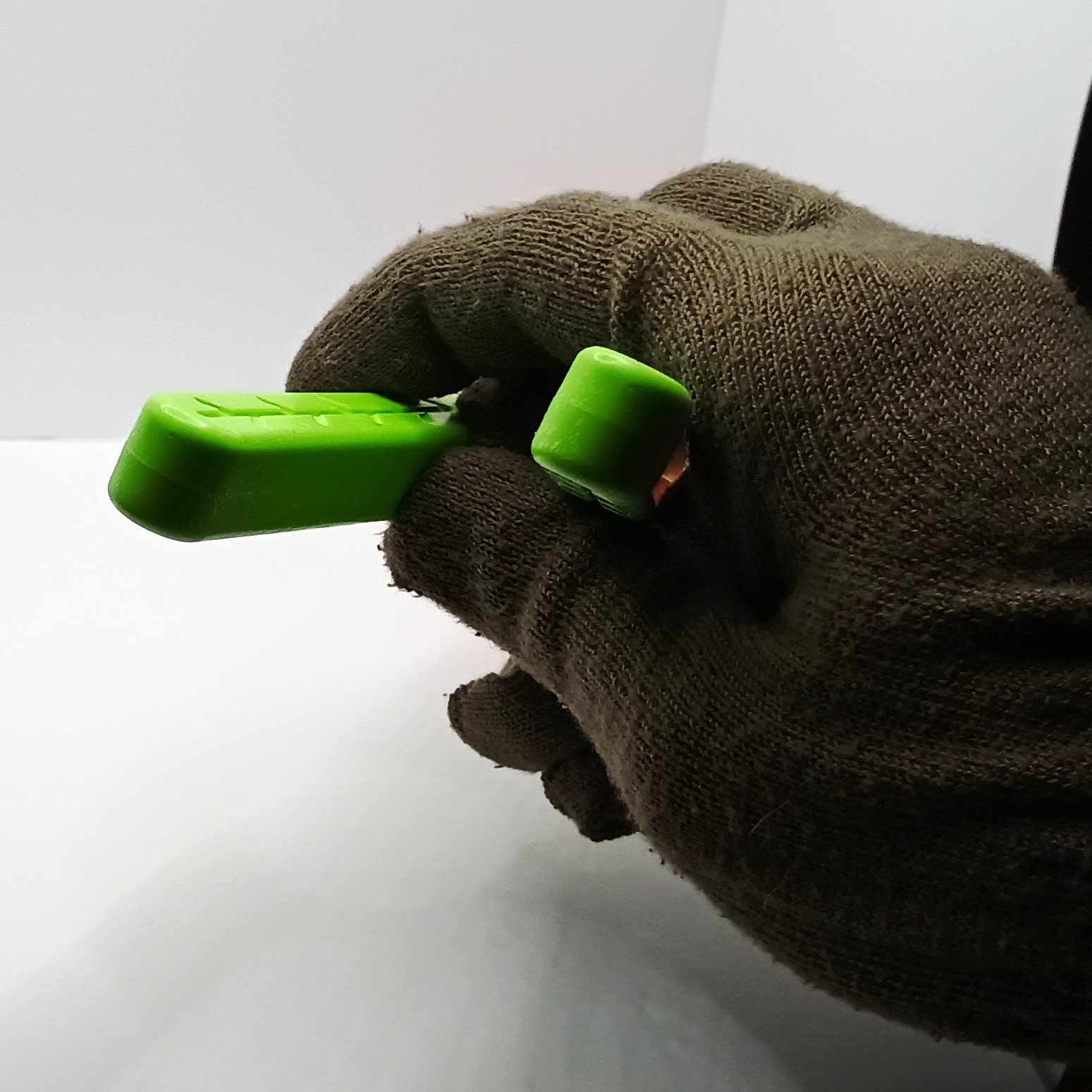

You get four screwdriver tips included out of the box: A #1 and a #2 Phillips, a 1/4" slotted, and a 3/16" slotted. On either side of the knife are two bit carriers that flip out from the sides and are spring loaded so they always snap back to be more or less flush with the handle scales.

The bits are just held in with friction which sounds like a recipe for disaster, but you'll note that with the holder in its home position the cutouts in the handles aren't actually long enough to make it possible for a normal length bit to slide out far enough to fall out. The holder has to be swung out to extract the bits, intentionally or otherwise.

I had to prop this one open by way of example (with the plastic cover from the end of a mini HDMI cable, if you're wondering).

And then, of course, you can also just use the bit socket with no bit in it to drive 1/4" hex head screws. You'll find lots of fasteners with combination hex-and-whatever heads are this size, for precisely that reason.

So the possibilities here immediately present themselves. With the included drivers you could probably completely disassemble any typical desktop PC, for instance. Or if you're a knife nerd like us you could swap out two of the bits for a T6 and a T8. Then you could use your knife to take apart your knives. Yo dawg, etc.

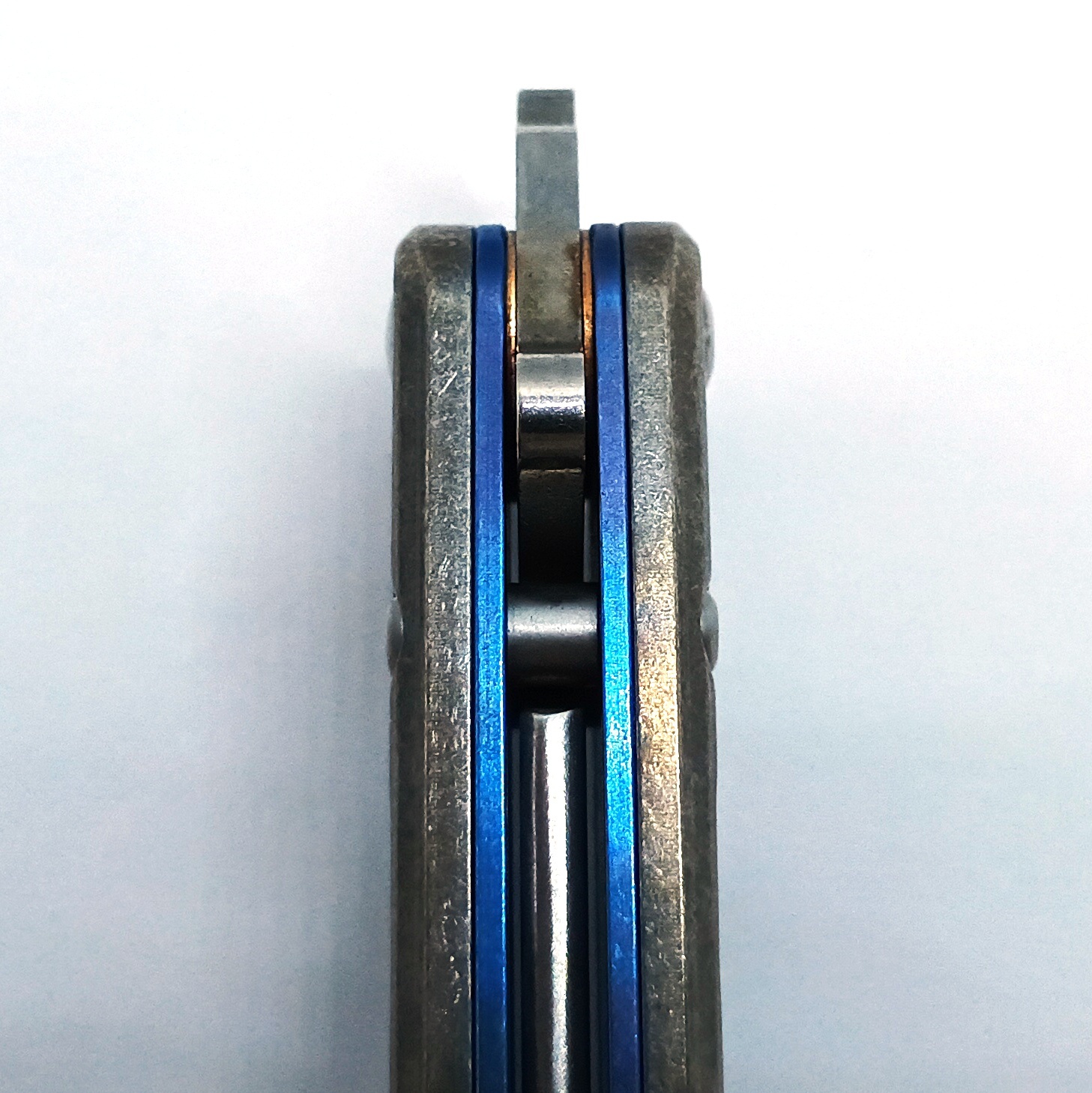

The screwdriver bit arm, or whatever you want to call it, detents in either a 90 degree...

...or 180 degree position.

It does so by way of a spring loaded crossbar in the tail of the knife that slots into a trio of notches in the heel of the screwdriver arm. That's visible here:

It detents into the closed position as well, of course, but does not fully lock in any position. So if you're really reefing on something, you'll want to be sure of your Direction of Application of Grunt so it doesn't fold up on you. If it does it should do no harm, but it'll still be annoying. Also, you can't fold the screwdriver arm up with a bit installed in it -- it won't clear the bottle opener.

The nice thing about the pivoting arm design on, this as opposed to the usual perfunctory short fixed socket often found on these types of devices, is of course the length. The extra reach is handy, plus there's the ability to lock the handle at 90 degrees for extra torque when required. You could in the right circumstances even use this to fish down in a blind hole for a screw. At least, provided the hole were big enough to allow for the diameter of the socket. It's about the same size as the tip of a dedicated exchangeable bit screwdriver, though, so that idea's not too far fetched.

According to the terms of various international treaties, all multi-function tools must by law have a set of largely useless ruler markings etched into them somewhere. In this case it's on the front and back surfaces of the screwdriver arm. There are fractional inches on one side and millimeters on the other. It's just about good for estimating the length of a screw, and not much else.

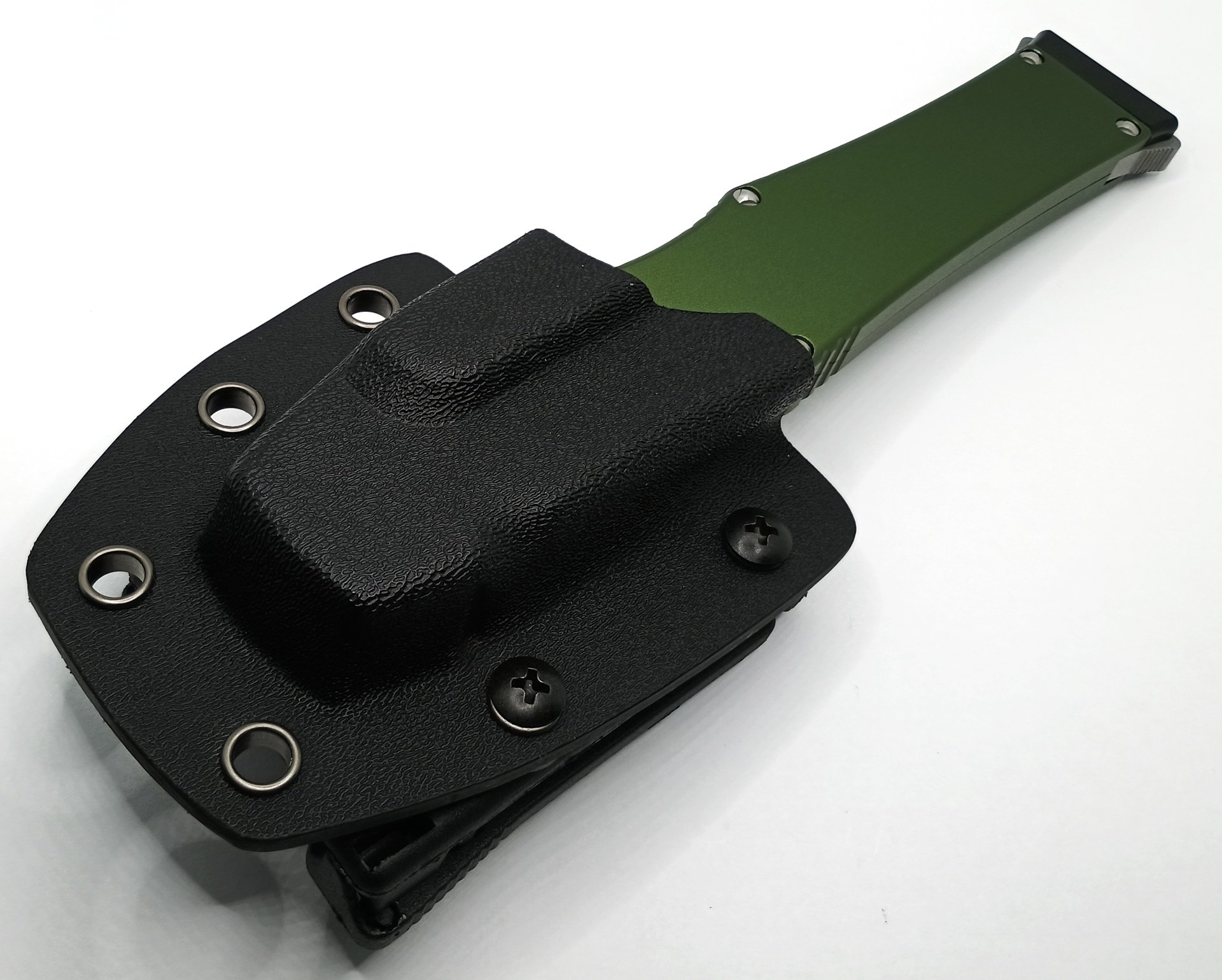

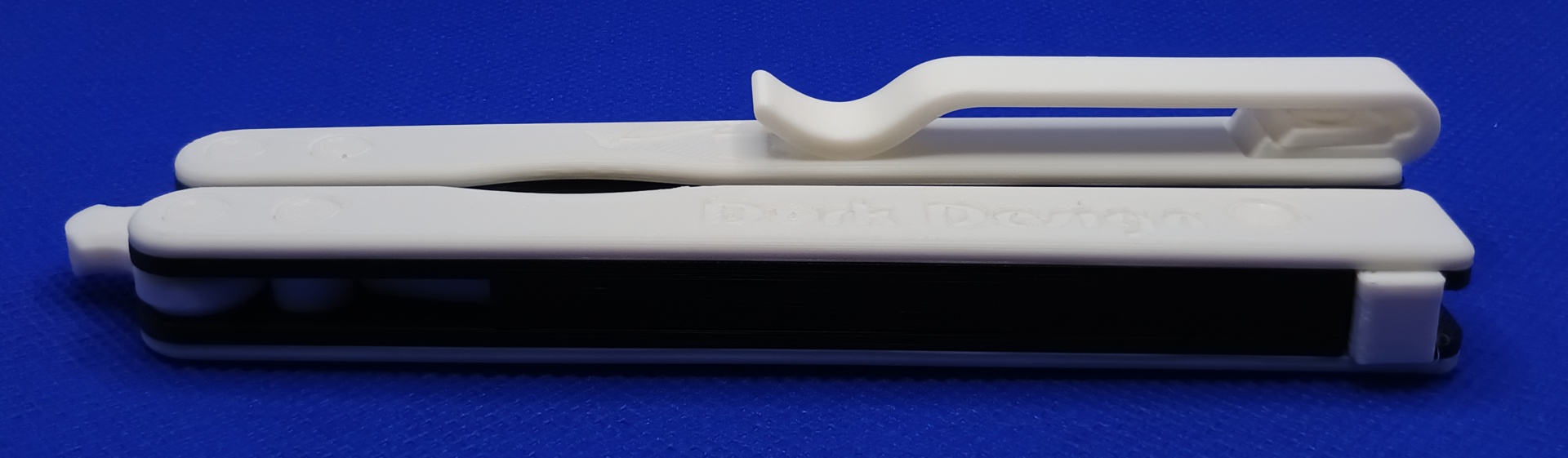

The actual knife part is a competent but ordinary liner locker with a 3-5/16" long drop point blade made of 8Cr13MoV. The blade is 0.114" thick at the spine, matte bead blasted, and has a hollow grind. A subtle belly is present towards the forward end, which you will notice if you look at it carefully. Fully open, the Select Fire is 7-1/2" long, and closed it's about 4-1/4". It's a chunky boy, too, probably mostly owing to having to pack in both the screwdriver arm and the pair of bit carriers in the handles. Mine weighs 147.1 grams or 5.19 ounces. Yours won't -- I'll get to why in a little while. The widest point appears to be just forward of the bit holder socket when it's folded: 1.438" or about 1-7/16". It's also quite thick, 0.655" or about 5/8" not including the clip, and 0.775" with it or 3/4".

Said clip is a pretty typical traditional design and is not deep carry. It is reversible, though, and dual thumb studs are present to ensure that the Select Fire is sufficiently ambidextrous. But the only option for clipped carry is tip down, which always fucks me up whenever I carry this knife because practically everything else I own is a tip up knife instead.

The clip is nicely engraved with the Kershaw logo. It's the real deal, not printed or painted.

The Select Fire is a true liner locking knife, not a frame locker, so you get the full sandwich of left and right liners and a matching scale on either side. The scales are injection molded and I'm pretty sure they're glass filled Nylon. Kershaw doesn't specify what they're made of but that's what they feel like to me.

They do, however, specify that this knife is a Grant & Gavin Hawk design. The G&G Hawk moniker is marked on the blade like so. Apropos of nothing, we have indeed looked at another Hawk design knife previously, and suffice it to say I think this one is a damn sight more useful in the real world. I also notice that the Hawk duo make a custom utility knife as well. Apparently now I have a rival in the world of bird-adjacent box cutter design.

And I'll tell you what, at an MSRP of $50 and a street price of about $35, the Select Fire is a damn sight cheaper than getting your hands on any of the in-house Hawk knives.

For your money you do get a knife made of what is without question a budget steel. 8Cr13MoV is identical in composition to AUS-8 stainless, and is an alloy probably pretty well suited to the use case this knife is likely to endure, i.e. careless use by tradesmen, Joe Six Pack, and other oiks who are not knife collectors. It's a decently tough steel in that it will resist the blade snapping better than many other contemporaneous options, and it is extremely corrosion resistant which is a plus for any owner who will believe "stainless steel" should mean "totally rustproof under all circumstances," even though you and I know it doesn't. Edge retention is 8Cr's weak point, but you can't have both edge retention and toughness at the same time without spending a lot more money on your steel. So, the marketing department will call it "easy to sharpen" instead.

As a budget folder and a liner locking one at that, I do have to point out that the blade in mine doesn't sit quite centered. That's not unusual for this sort of knife, since liner and frame lock mechanisms inherently have a force pushing the blade to one side at all times when they're closed. It's all gravy, though -- even with this, the blade does not actually contact either liner during operation.

The Select Fire is a plain folder and not spring assisted, which is a trifle strange because the bastard is already loaded to the gills with springs anyway. One more probably wouldn't have broken the bank. The pivot action is pretty nice, though, and as is typical for Kershaw knives it locks up positively and solidly with minimal wiggle in the blade in either direction once deployed.

So, about springs.

At first I didn't intend to take the Select Fire apart for this column. I figured there probably wasn't anything in there to see that anyone would care about, so the original plan was to just look at it from the outside, rack up the usual shitload of stacked focus macro photos, maybe make a joke about not being able to use something to take itself apart, and then on to the next thing.

But I did take the Select Fire apart, and I'm glad I did. Because if you're the same kind of idiot I am, there are a couple of design surprises inside you might find interesting. If you aren't, well, you can go away or scroll to the bottom for the wrap-up. The construction details of the Select Fire are likely to appeal to Select People. (You see what I did, there.)

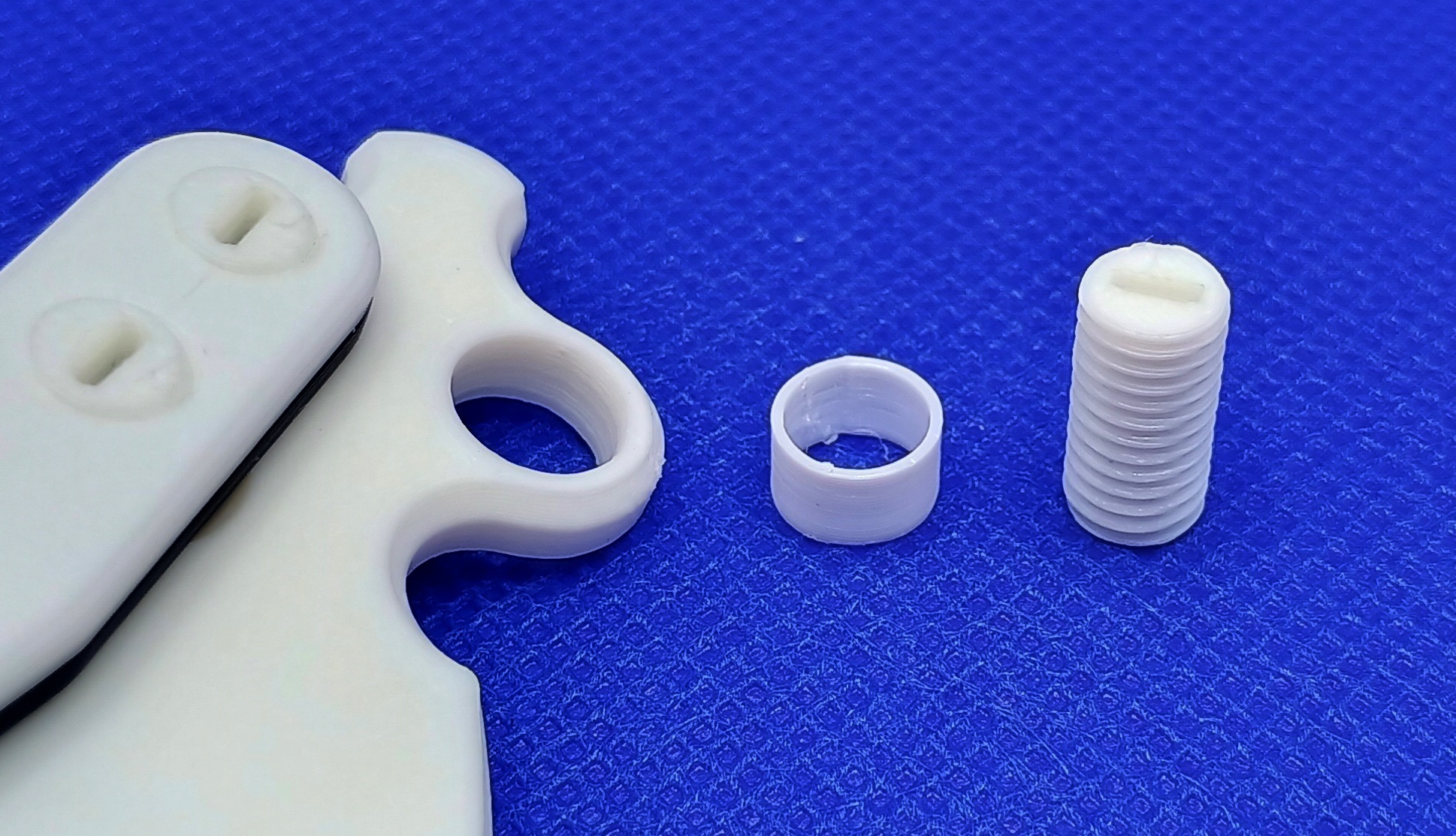

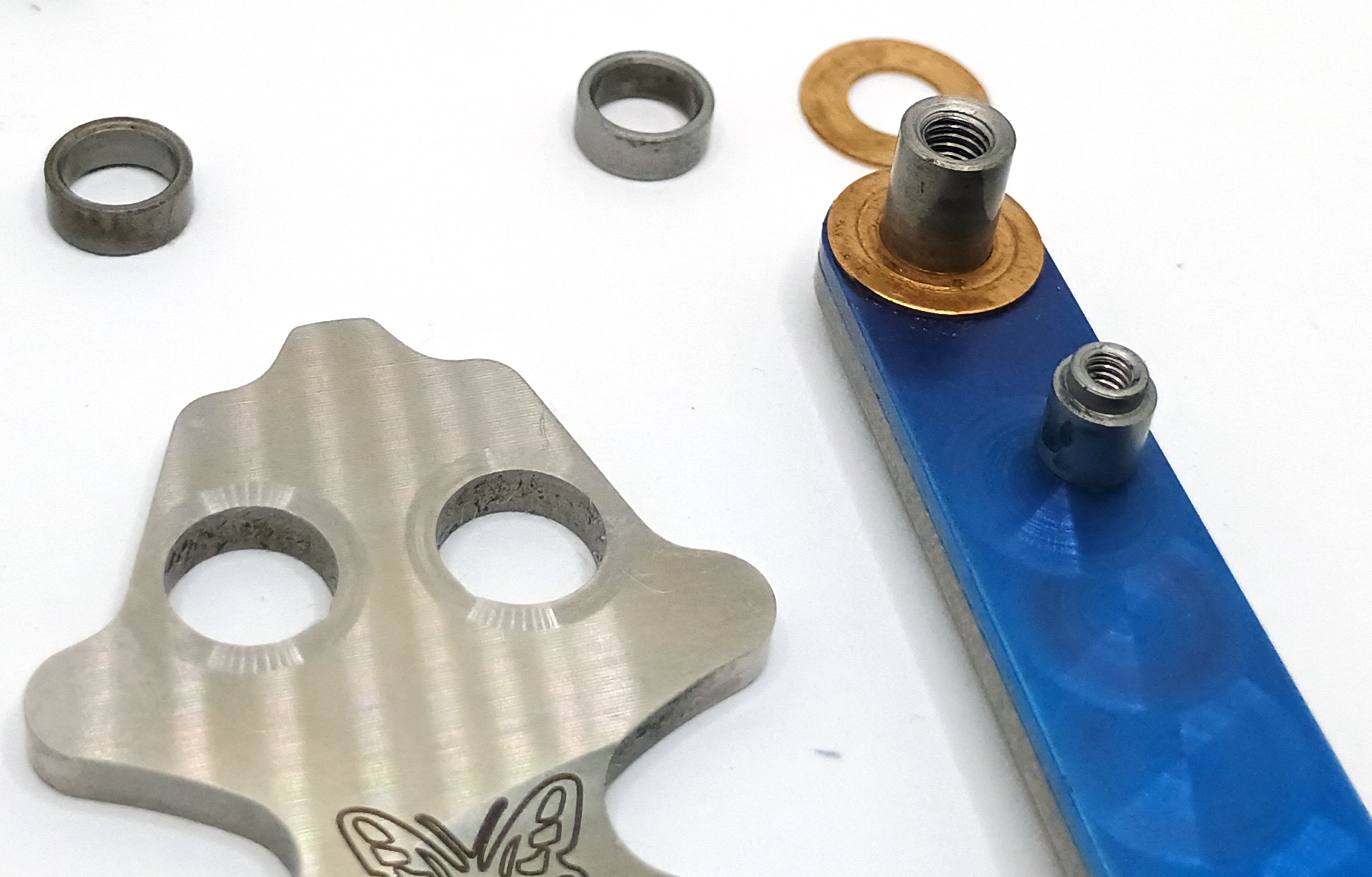

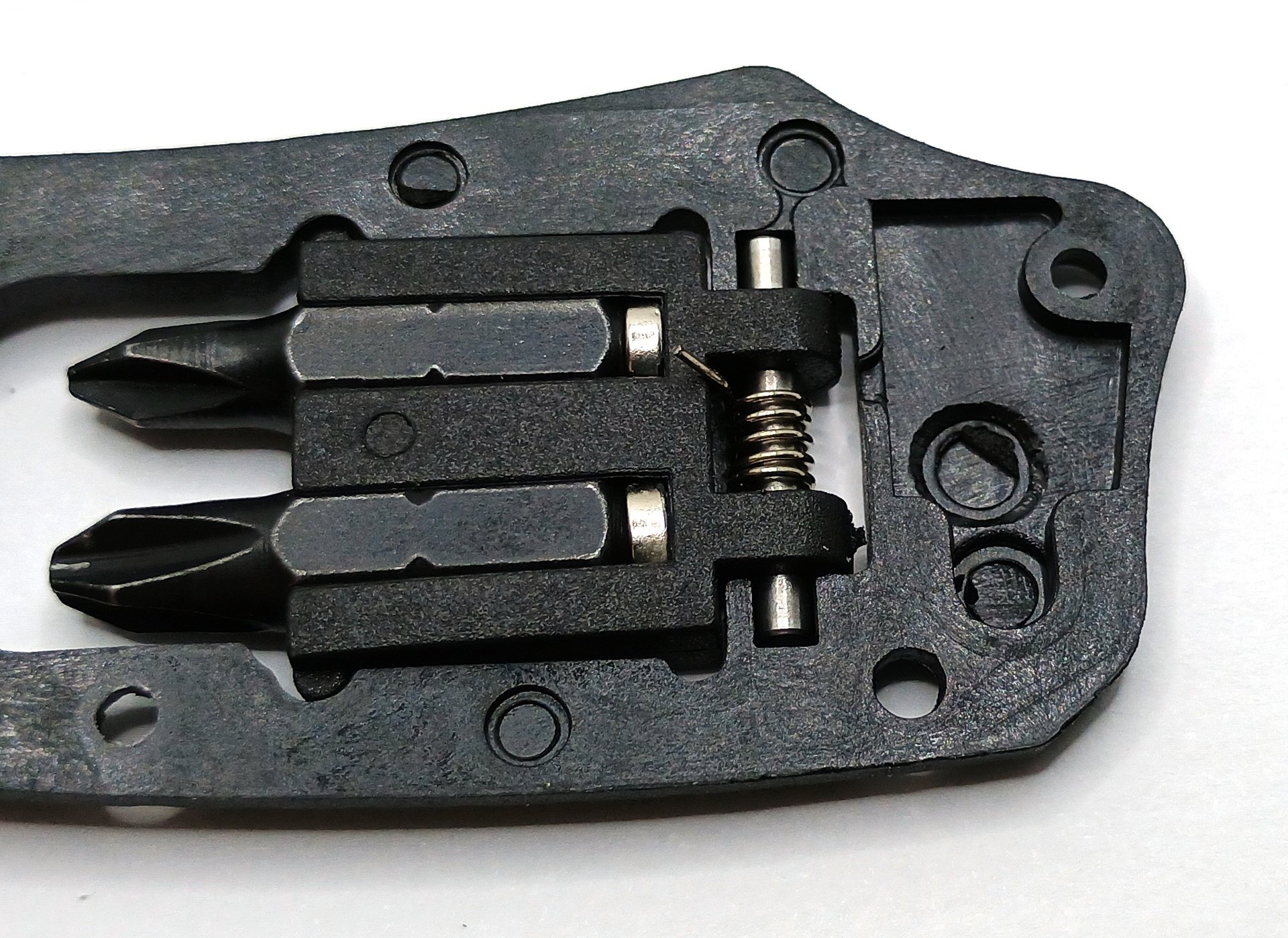

The reason I took it apart is something the eagle eyed among you might have already noticed, which is that the blade pivot uses Nylon washers but the screwdriver arm pivot has phosphor bronze ones. So that's odd, and I wanted to take a closer look.

On the way, I found this. The Select Fire has a complete separate superstructure underneath the scales. At first blush that's not unusual for a liner locking knife. Obviously it has to have liners under the scales, I mean, duh. It's right there in the name. But the Select Fire has a secondary set of screws holding it all together underneath the scales, totally independent of them, and thus could function without the scales mounted at all if you wanted to. You wouldn't want to, but you could. Normally a knife like this has all the screws pass through the scales and the liners all in one go, directly into whatever it uses for spacers.

So with that there are an absurd number of screws in this knife. 19 in total, if you count the ones for the clip. And it is separated by the endstop pin and one diabolo shaped spacer, down there in the tail.

What I didn't expect was to find that the detent bar for the screwdriver is loaded with a tiny Axis style Omega spring. It's just so twee and lovable. I adore it totally. There's one on each side.

To accommodate this, there is a complicated pocket molded into the back side of each scale. I suspect this is why there are no mounting holes for the clip on this end to allow tip up carry; They'd conflict with the spring. So for that reason, I'll excuse it... just this once.

The two spare bit holders swivel on pins that are sandwiched between the scale and the liner. They're sprung with one torsion spring each, which when the knife is fully assembled rests in a slot in the back face of the scale. However, anyone who takes one of these apart will quickly discover that this spring will pop out of place pretty much as soon as the scale screws are removed. How it goes back in is not immediately apparent if you don't understand how the mechanism works.

Upon reassembly, you'll want to slip something in between the spring and scale like a small screwdriver to hold the end of the spring in place and keep it from incessantly flicking itself back out into precisely the position you don't want it to be in. Pinch the scales together and hold them that way until you get the two rearmost screws in.

The Select Fire is about the same overall length as my usual CQC-6K we use for comparison purposes around here. It's broader in the beam, though, possibly with some breadth intentionally added to accommodate the spare bit holders. At over 3" in blade length it is unfortunately too large to carry in some locales. You know which ones fixate pathologically on that particular limit for whatever reason. For prospective owners who are unfortunate enough to live in such hellholes, consider instead the Kershaw Shuffle DIY, which is much the same idea but has a 2-1/2"-ish blade instead. But it also loses the extra length on its screwdriver bit socket.

With such a smorgasbord of moving parts, the Select Fire is probably also a strong contender for the title of King of the Fidget Knives. It's like a toddler's busybox but for strange adults. Not only can you mess with the blade pivot, but both bit holders swing in and out and spring back into position with a satisfying click, and you can diddle with the screwdriver arm as well. Or whirl it around like a helicopter with it in the 90 degree position.

The Inevitable Conclusion

This may not be the knife most people think they want, but it's probably actually the knife most people should have.

We tend to fixate on the knife aspect solely, and fixate on it in a particular way. Well, of course we would, right? This is a knife community, and this is a column about a knife. But overall we tend to hyperfocus on things like the alloy of the steel, the aesthetics of the scales, the cleverness of the mechanism, and the snappiness of the draw. And we make up silly scenarios and use cases to justify all these as if we're likely to need to pull the thing on zombies in a hurry. Or if on a daily basis most of us need to use a pocket knife to split logs. Or maybe use the damn thing as a piton.

But, well, we don't. Come on, be honest.

By and large most of us stupid monkeys don't live our life on the veldt anymore. We live it in a manufactured world. There aren't trees to chop down or tigers to fight off with our knives -- but there are frequently encountered screws. Lots and lots of screws, all over everything, holding our modern jungle together.

What most modern people use the knife part of their knives for, even though they will never ever admit it unless pressed very hard -- possibly in a vise -- is not actually really critical work. It's opening boxes and mail. It's cutting tape and rope. And cleaning fingernails, and coring apples, and chopping the tag of the back of your shirt. And the other perennial favorite, of course, is incorrectly using the tip of the blade as an impromptu screwdriver (and promptly snapping it off). Well, you're already holding the tailor made solution to that in your hands right here.

And all that's just those people who even carry a knife on a daily basis at all, which I am sure is a slim minority in our current century. All of the above is why so many even out of those of us who do have cruised along just fine with nothing more than a regular Swiss Army Knife, which in objective terms is, actually, terrible at the knife part of being a knife.

The Kershaw Select Fire isn't. It is a very decent, very competent knife. It is a knife first, just as I outlined many paragraphs ago. But it also includes a very serviceable screwdriver. One that is actually better at its job than most multi-function tools that are also worse knives in the bargain. There are "better" and fancier knives in the would -- and more expensive ones, sure. But will they do this for you?

Just yesterday while I was doing the photography for this column a thunderstorm blew through and I paused what I was doing to go stand at the back door and watch. It was then that I noticed the downspout by the back door was overflowing. So after the storm passed, I climbed up there to have a look. The downspout elbow was clogged with washed away stray nesting material and shingle grit and maple tree whirlybirds who knows what else, and it was clogged up far enough down that I couldn't reach all of it.

I mean, of course it was.

But I still had the Select Fire in my pocket, so I used it to take the screws out of that chunk of downspout -- a task at which it excelled -- right then and there. Unavoidably, I got muck all over myself in the process. And my knife. So what if I did? This knife has no collector's value to scuff. And I got the thing unclogged and put back together with no other hassle at all.

It is stories just like these, told a million times a day, that make up our collective civilized world. Nobody is actually slaying zombies with their damn knife. Nobody is fighting terrorists with it, either. Very few are in the woods actually doing any "survival." Nobody's skinning game they've just killed with their teeth, or whatever the fuck else the manufacturer of that expensive knife is hoping you're fantasizing about with enough lack of clarity to finish typing in your credit card number.

But there are things to mend. Everywhere, all the time. Just now my Select Fire saved me from a damp and grumbling trudge across the grass to the garage to get a screwdriver. And next? Who knows. But I'll have it and because of that I'll be ready.

For most of us, a knife like this is probably a better daily companion than the several-hundred-dollar, designer steel, carbon fiber scale, titanium liner, individually serial numbered, custom anodized clip, drawer queen of a bauble you just saw on the front page of your favorite knife web site, whatever it was. I've said it before and I'll keep saying it because it'll never not be true: The knife you will use is a better knife than the one you won't, no matter what either one costs.

Postscript

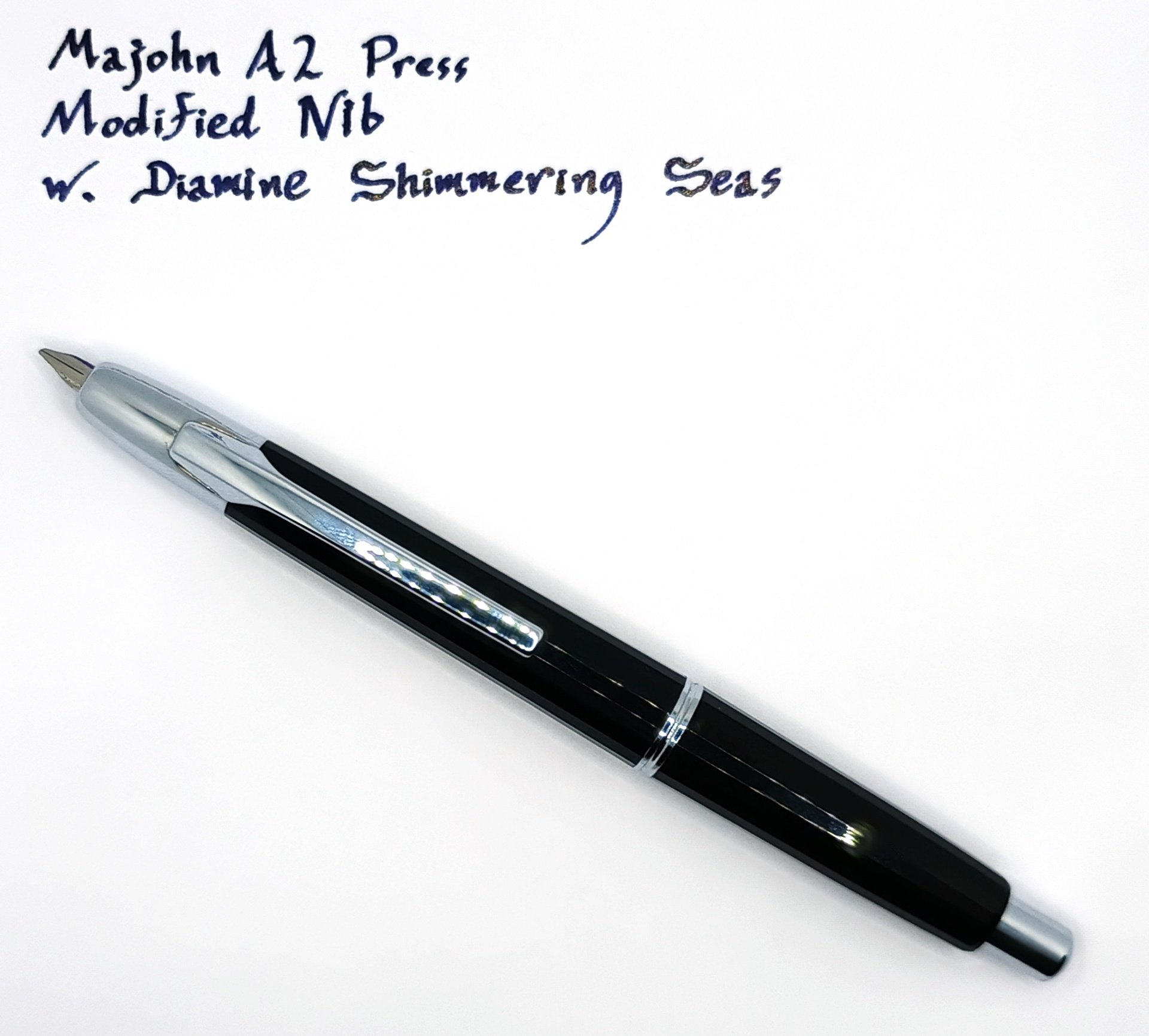

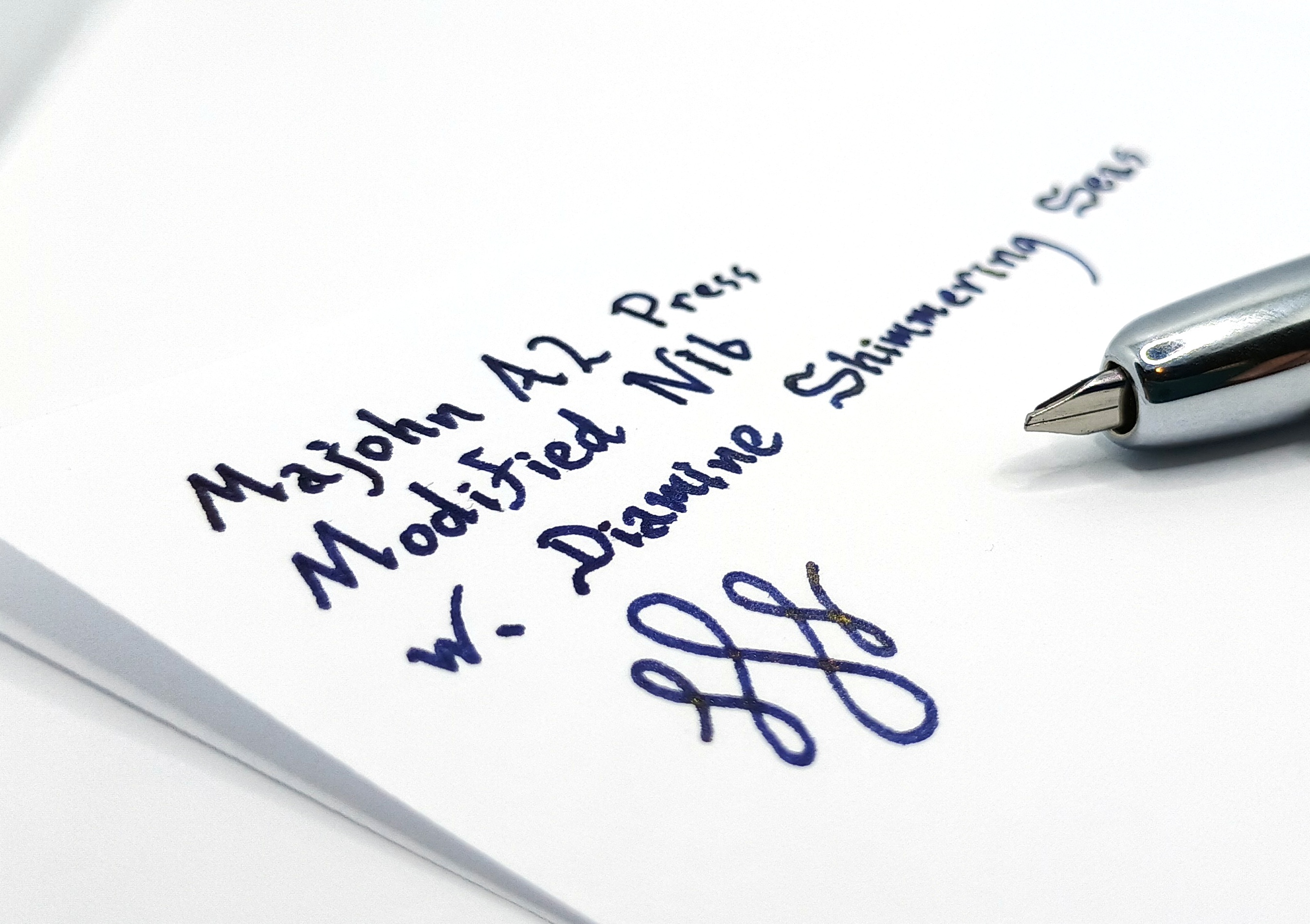

Oooh, a bonus feature.

I mentioned that my Select Fire weighs more than yours will. Okay, not by much. But still. That's because I made a slight modification.

As stated, the screwdriver bits can't actually fall out while the knife is knocking around in your pocket, because the cutout they rest in isn't long enough for them to fully slide out of their holders. But sometimes mine do still come loose, and then I find them still captive but all higgledy-piggledy in there. This annoys me, even if only just for the principle of the thing.

So given that I am already, shall we say, invested in Zack Freedman's Gridfininity system for unrelated purposes, I tend to have a ready supply of 2mm x 6mm neodymium button magnets lying around. 1/4" is 6.35mm. I think you can already see that these are the perfect size to interface with a typical quarter inch screwdriver bit. So I glued one magnet into the bottom of each screwdriver bit slot, and now they stay neatly in place no matter how hard I shake, tap, or tumble the knife around.

Nirvana: Achieved.

Not weird enough for Wednesday.