3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

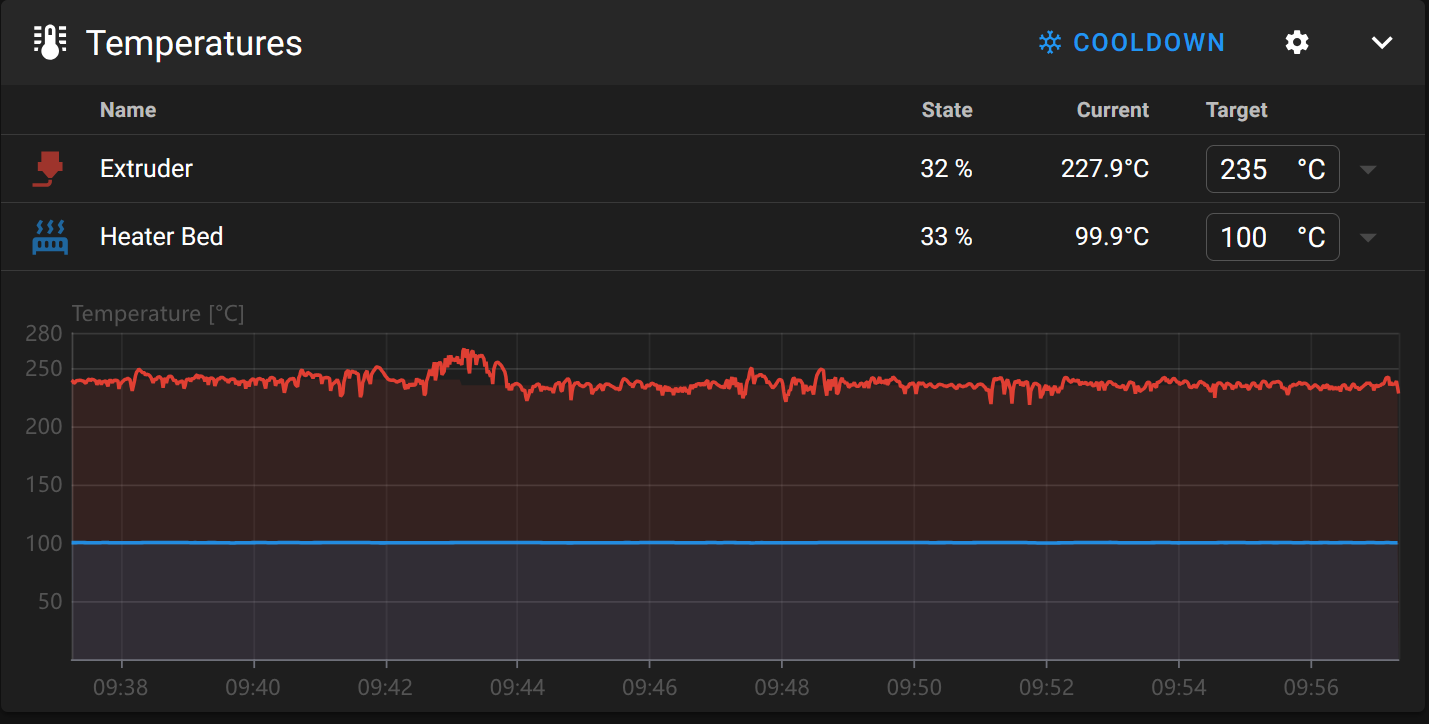

That was me, but in that case it was the heater wire and the break was in the y-chain. This break is in the x-chain. Based on a reply on the Voron design forum, I may not have left enough slack in my wire runs. The breaks always happen on the inside radius, right where a wire touches one of the links in the chain, so this seems like a decent theory.

I think I'm going to completely rewire the hot end. On the fence about going to USB or CAN vs discreet wiring. Since I tend to print big things, I don't think an umbilical is a great idea - it seems like it would not work that well in high z situations. My reverse bowden already snags things sometimes.

I left probably too large loops in those places, but I've seen some nasty cable breaks when I worked with pipeline inspection tools so I'm kinda paranoid about having enough slack.

Umbilical folds on itself pretty well, I probably have mine too high tbh, but I could see a tophat mod being a thing. What you gain in less wires with can, you do add complexity to your overall setup, ran into some timeout issues after upgrading my SBC which seems to be related to this crowsnest issue thread that I've got sorted. Usb toolheads are a good idea, I went can because I'm using that for an ercf anyhow and already had bunch of usb devices.

I had no idea about cable chain slack when building :( I wouldn't call the wires tight, but they're not super duper loose either.

I work in automotive and have a bit too much experience with CAN. It is appealing to have fewer wires in the chains, but so far wire breaks have been super easy to find/fix. I'm somewhat tempted to give chains with discreet wires another go. It shouldn't take more than 4-5 hours to have a cut and crimped to lenth harness installed.

I am tempted to start researching a BOM for USB + top hat though.

Last time I used can was for battery controllers on one tool family back in pipelining, people kept losing or forgetting the terminators.

There's the nighthawk toolhead for Stealthburners that's one of those usb umbilical boards, and did look at this printable tophat in the past.

I definitely ran spares in my cable chain as the less I need to open them the better, if I did discreet wiring on a new build though I very much might consider running something like a multi conductor cable through the cable chains with a smaller one for power+ground, build in some allowances for spares just to be safe.

The nighthawk looks interesting. I'm somewhat tempted to give it a go, but I'm not sure about ditching the chains for a top hat yet. All the multi conductor cables I looked at that are USB rated are not rated for the tight bend radii found in the Voron chains :(