it seems a very niche use case, The algo is not sub-optimal, It's just not meant to be watertight, and trying to make the infill water tight would likely detract from what it Is meant to do.

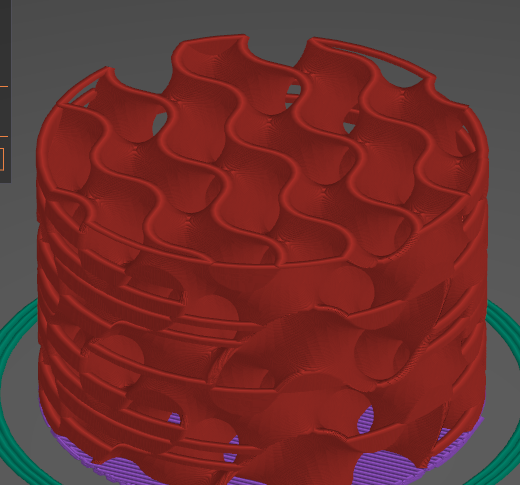

namely provide support for printing layers above it and increasing structural strength. That said, I've been puttering in prusa with gyriod, and it appears to create a sealed surface by going to 1mm extrusion widths, and .1mm layer heights at 25% infill. .2mm @ 30% infil also appears to be fine (but there's small gaps where it seems to anchor.)

As far as handling overhangs better, part of the problem with going too thin on layers and overhands is there's less material and it gets flimsy for the first few layers. you can easily extrude at 1mm widths with a .4mm nozzle without it looking too hideous.

this actually gives me an idea for a lamp shade, heh. Imagine, if you will, neopixels running in each section at the base.